Blog/ EduLab

🔋 ProLogium EduLab|Logithium Frame Adhesive Separation Structure

Press Information

Dec 19, 2025

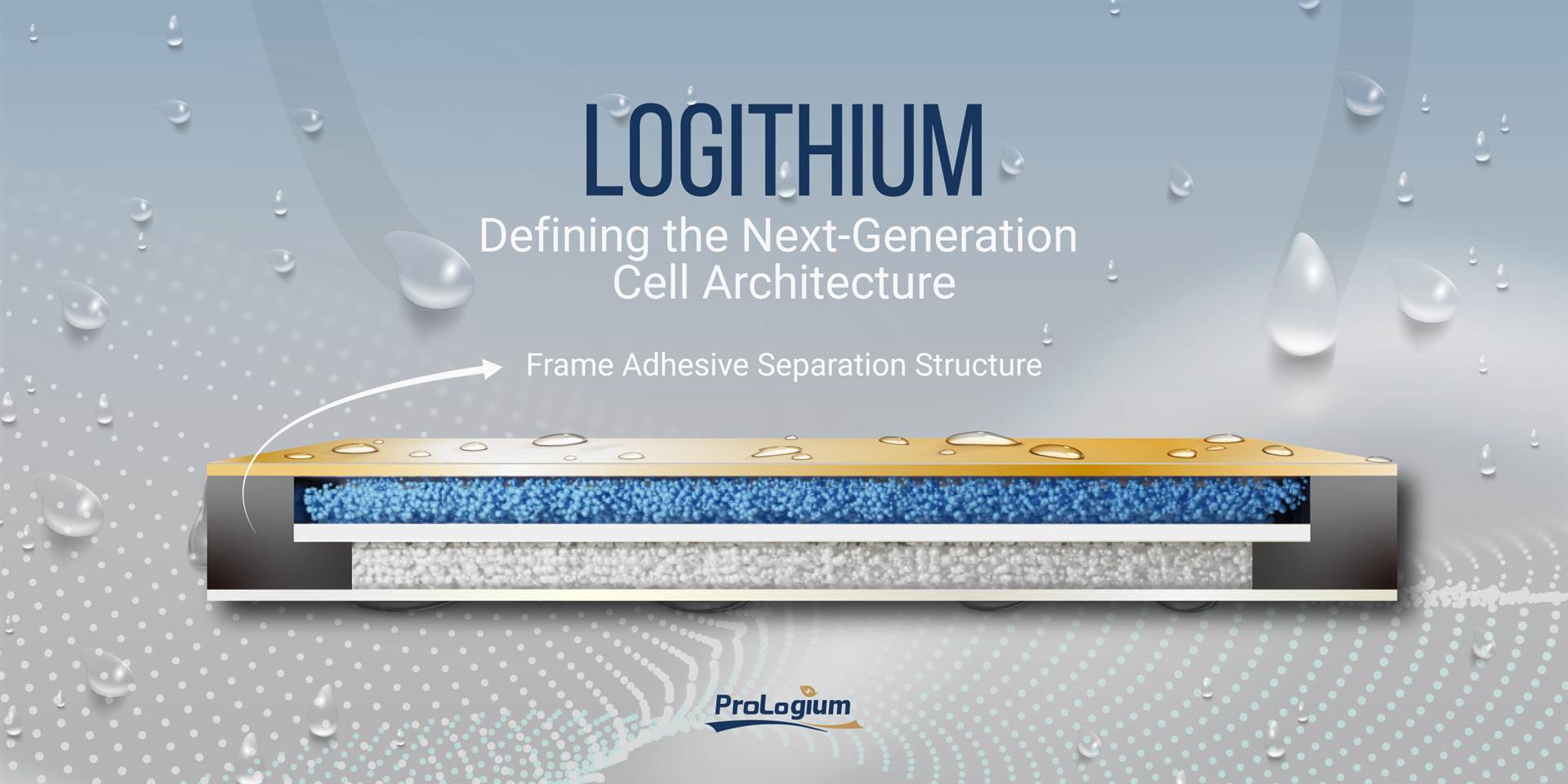

A cell is built upon four fundamental components that store energy: the cathode material, anode material, electrolyte, and separator. To ensure stable and reliable battery operation, additional elements such as conductive materials, binders, and frame adhesive structures also play critical roles. Today, we introduce one of the core cornerstones supporting ProLogium’s next-generation battery technology development and mass-production platform: the proprietary Logithium Frame Adhesive Separation Structure.

Batteries have extremely high requirements for environmental and structural stability. Beyond high and low temperatures affecting safety and performance, moisture and short circuits are two critical risk factors for safety concerns. Through Logithium technology, ProLogium prints frame adhesive material onto the electrode layers, simultaneously preventing external moisture penetration while serving as an additional separator to prevent edge short-circuit risks, protecting the internal chemical system and further enhancing cell structural stability and overall safety.

✨ Six Key Advantages of Logithium Technology:

- Thermal Stability: Maintains structural stability in both high and low temperature environments

- Dual Protection: Functions as an additional separator, strengthening water resistance and short-circuit prevention capabilities

- Cost Optimization: Eliminates the need for large-scale dry room processes, significantly reducing manufacturing costs

- Process Innovation: Enables high-speed roll-to-roll manufacturing processes for solid-state batteries, establishing a foundation for mass production

- Technology Extension: Transforms cells into independent components, enabling flexible stacking architectures and series-parallel connection technologies

- Easy Maintenance: Allows for individual damaged cell replacement, suitable for modular design

ProLogium obtained the Logithium technology patent in 2010 and has since derived 286 related patent technologies. This innovation not only established an important reference framework for frame adhesive design and manufacturing processes in solid-state batteries but also became the developmental foundation for ProLogium’s subsequent key technologies.

In our next post, we’ll explore the Bi-Cell thick-film technology extended from this innovation, revealing how ProLogium continues to breakthrough in energy density and cost structure. Stay tuned!