Press Releases/ Announcement

The World’s First “Superfluidized Inorganic Solid-State Electrolyte” Paves the Way for Full-Scale Commercialization of Next-Generation Solid-State Lithium Batteries

Press Information

Jul 30, 2025

At this pivotal moment when solid-state battery technology is rapidly reshaping the global energy landscape, ProLogium Technology officially unveils its fourth-generation disruptive innovation – the Superfluidized Inorganic Solid-State Electrolyte, marking the beginning of a new era for solid-state lithium batteries — one defined by full functionality, wide applicability, and scalable mass production.

This groundbreaking electrolyte technology combines the high ion concentration of solid materials with the excellent interfacial contact properties of liquids, to overcome three major bottlenecks of traditional solid-state batteries – ionic conductivity, interfacial stability, and manufacturing efficiency. As a result, it delivers five critical performance advantages in one integrated solution: high conductivity, enhanced safety, fast charging, low-temperature operation, and no need for pressurized modules. This innovation establishes a key platform for the commercialization of next-generation battery technology.

Building on this achievement, ProLogium is advancing a collaborative framework of technology licensing, strategic alliances, and regional manufacturing. By focusing on its proprietary technologies—superfluidized inorganic solid-state electrolyte and advanced electrode modification—ProLogium aims to enable end-to-end industrial deployment, from materials and processes to modules and applications, to co-create a new paradigm with its partners for the global battery industry.

Setting a New Industry Standard: Performance, Safety, and Cost in One Integrated System

Since its founding in 2006, ProLogium has remained dedicated to inventive R&D in solid-state lithium battery technology, amassing over 1,000 patents worldwide. Its newly unveiled fourth-generation technology—the Superfluidized Inorganic Solid-State Electrolyte—represents the culmination of nearly two decades of innovation. It integrates breakthroughs in high ionic conductivity, intrinsic safety, simplified manufacturing process, and optimized material costs. The result is a fully functional, mass-producible system-level solution for solid-state batteries that establishes a new industry standard in performance, safety, and cost-efficiency, accelerating the path to real-world use cases and global deployment of next-gen batteries.

World-Leading Conductivity and Ultra-Fast Charging Capability

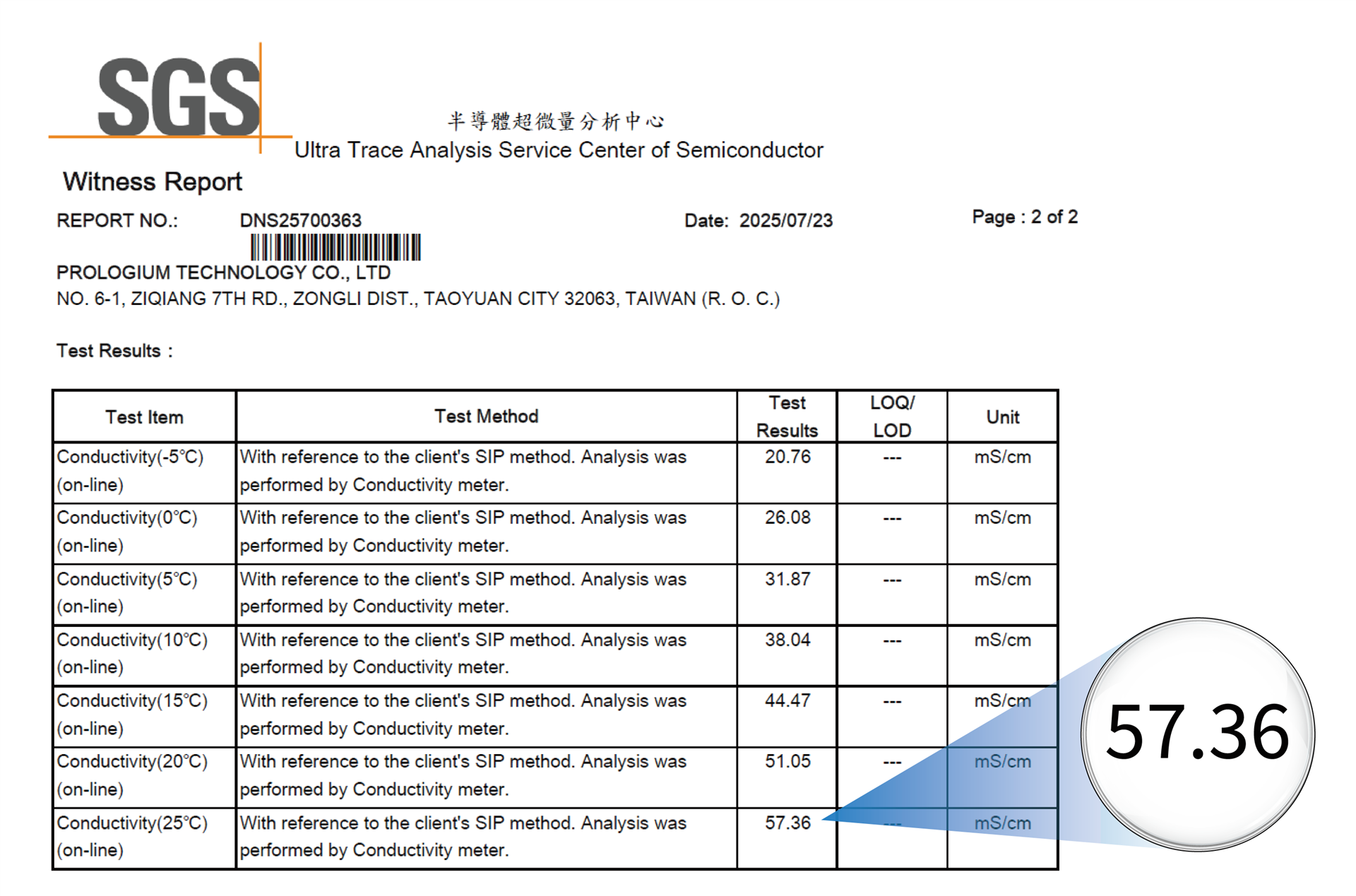

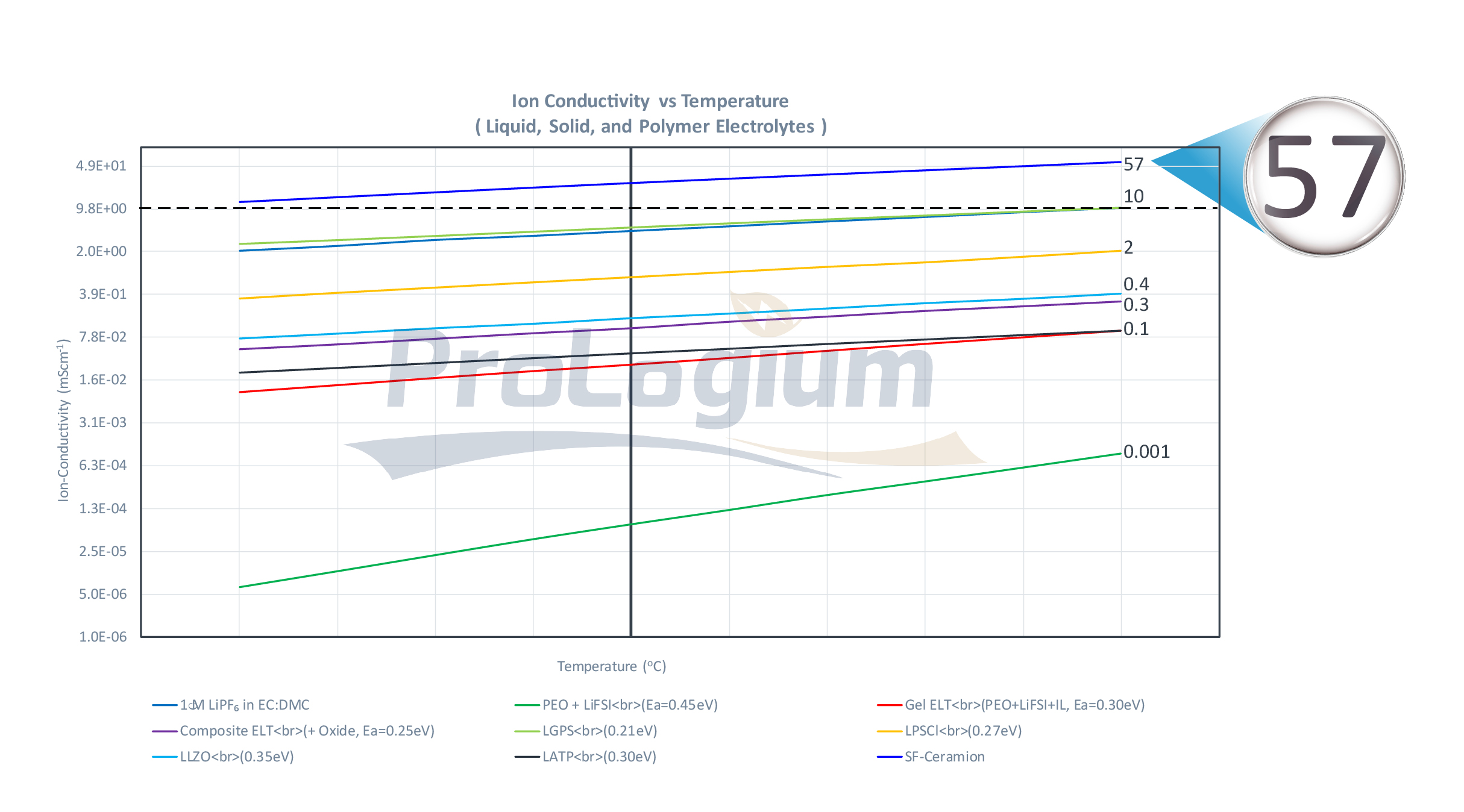

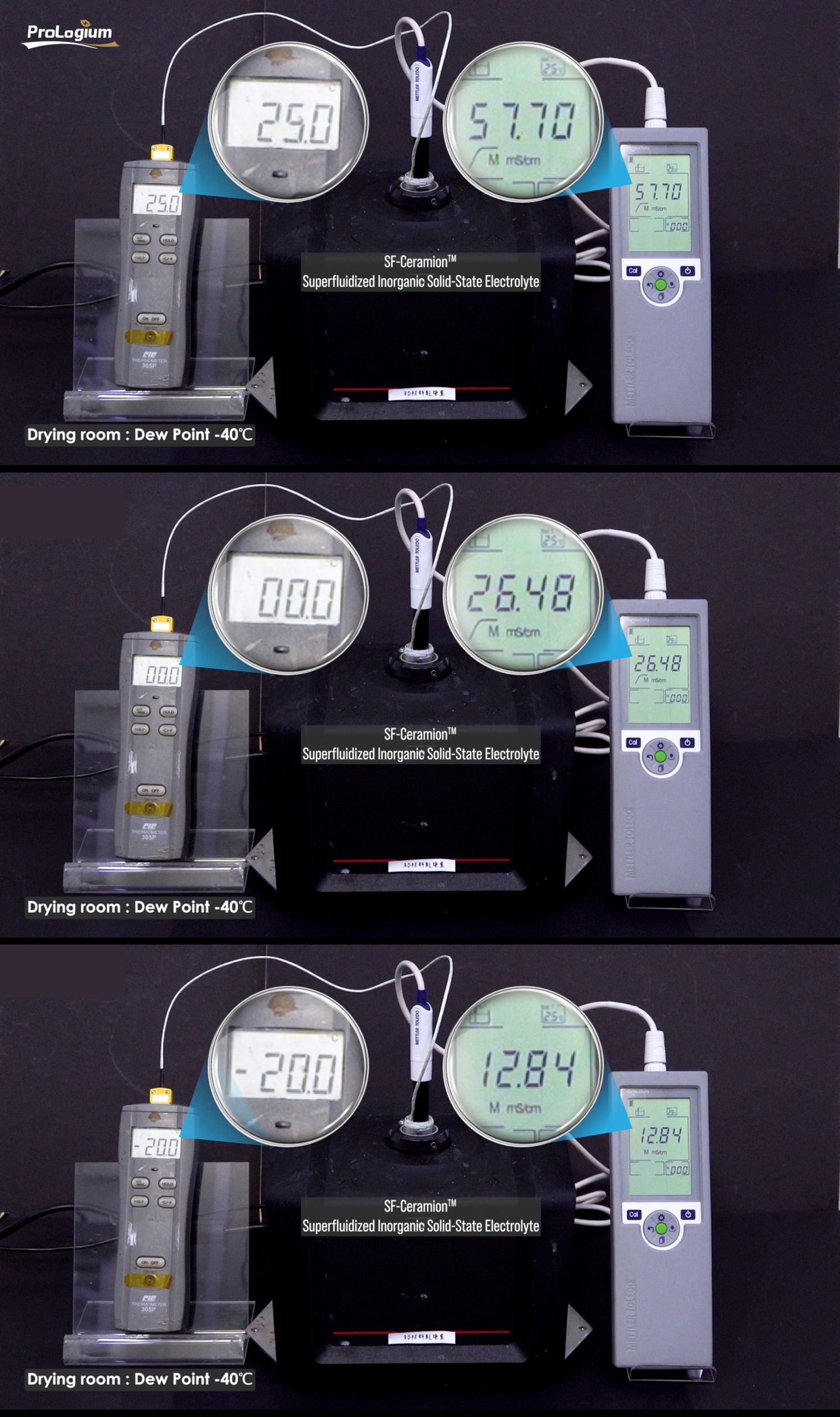

Batteries containing this fourth-generation electrolyte system have achieved a world record for ionic conductivity, as verified by SGS, a third-party testing, inspection and certification company. The ion conductivity at room temperature is as high as 57 mS/cm, approximately 5 to 6 times higher than existing conventional organic liquid electrolytes and sulfide solid electrolytes. This performance enables high-energy-density batteries to achieve 5% to 60–80% charge within just 4–6 minutes. This revolutionizes the fast-charging experience and will significantly accelerate the rollout of passenger EV charging infrastructure and

SGS report

At 25°C, ProLogium’s fourth-generation SF-Ceramion™ electrolyte demonstrates an ultra-high ionic conductivity of 57 mS/cm, significantly surpassing existing liquid, solid-state, and polymer electrolytes. This firmly establishes its industry-leading position in conductivity, low-temperature adaptability, and mass production stability.

High Conductivity Maintained Even in Low Temperatures

At -20°C, the SF-Ceramion™ electrolyte still achieves an impressive ionic conductivity of 12.82 mS/cm, exceeding the room-temperature conductivity of conventional organic liquid electrolytes and sulfide solid electrolytes. Discharge efficiency remains at 90–95%, significantly outperforming traditional batteries that experience severe performance drops under low-temperatures.

Stable Output in Low-Temperature Environments

Even in environments as cold as -20°C, the system retains more than three times the lithium-ion conductivity of conventional batteries. Combined with its strengths of high migration and concentration, the system delivers 90–95% discharge efficiency for automotive use— a stark contrast with typical 50–60% performance decline of traditional batteries under low temperatures. This breakthrough eliminates range anxiety for EV users in cold climates and offers critical competitiveness for deployment in polar regions, as well as in defense, aerospace, and other demanding domains.

Breakthroughs in Materials and States of Matter Solve the Key Interface Challenges

Through its proprietary fluidization technology, ProLogium has successfully endowed solid-state electrolytes with the interface adaptability typically seen in liquid electrolytes. This allows the electrolyte to conform to the surfaces of active materials, which undergo dramatic volume changes during charge and discharge cycles. The result is long-term cycle stability without delamination or increased internal resistance, and save the need for external pressurization modules or structural compensator units such as pressurizers. This reduces system complexity and increases energy density.

Leading the Industrialization of Solid-State Lithium Batteries

This technological milestone confirms that solid-state batteries are not only scalable for mass production but also capable of meeting the industry’s three key requirements: performance, safety, and cost-effectiveness. ProLogium’s independently developed electrolyte system stands as a pivotal enabler for the full deployment of solid-state lithium batteries in all use cases. Going forward, ProLogium will continue to unveil more core technologies and drive strategic collaborations to accelerate the global rollout and adoption of next-generation energy solutions.

Technology Licensing for Industry Co-Prosperity

As its fourth-generation Superfluidized Inorganic Solid-State Lithium Battery technology enters the commercialization phase, ProLogium is launching an open collaboration strategy aimed at global implementation and industry co-prosperity across materials, processes, and product platforms. This marks the company’s evolution from technological innovator to global industry leader, laying the foundation for a scalable value chain that will accelerate energy transition towards net-zero goals. Strategic partners include material suppliers, equipment manufacturers, module/system integrators, and end-use customers, forming a matrix of deep-tech and broad-market engagement across the entire battery value chain.

Dual-Track Strategy Creates a New Model for Value Co-Creation

In parallel with licensing its core material technologies, ProLogium focuses on the manufacturing of inlays—the internal chemical systems of battery cells. Inspired by the vertical specialization model of the semiconductor industry, ProLogium produces inlays for its strategic partners such as cell manufacturers, module assemblers, or OEMs, who complete the final assembly and deploy use cases. This open collaboration model breaks the mold of the closed value chain of traditional lithium batteries, enhances integration across sector verticals and promotes shared innovation and value creation.

A Plethora of Use Cases Expand the Next-Gen Energy Landscape

ProLogium’s technology is applicable not only to electric passenger vehicles but also commercial trucks, construction machinery, robotics, aerospace, marine propulsion, and AI data centers where large-scale energy storage is required. To meet the differentiated needs of various verticals, ProLogium adopts an open alliance strategy, working with local partners who possess manufacturing capabilities and industry experience to implement regional production, module integration, and technology upgrades. To further accelerate market penetration and strengthen customer service, ProLogium is also introducing licensing and exclusive distribution systems. This enables qualified partners with strong channels and service capabilities to engage in local sales, post-sale support and technological deployment for customers. Commercial terms and rights are tailored to specific roles in manufacturing, integration, or distribution. This approach delivers flexible collaboration and shared benefits, reinforcing ProLogium’s global presence and sustainable foundation in the solid-state battery value chain.

Building a Global Alliance to Reshape the Energy Order

ProLogium is currently in discussions with multiple global players involved in materials, equipment, module integration, and energy applications for joint production lines, process implementation, and application standards. Looking ahead, ProLogium will integrate strategic investment mechanisms to build a next-generation battery industry alliance powered by technology, capital, and production capacity ProLogium firmly believes that open innovation, value sharing, and collaborative specialization are essential to drive the large-scale adoption of solid-state batteries and the global energy transformation. From its roots in Taiwan to its strategic foothold in Europe, ProLogium is building a localized global presence with deep technology, commercial agility, and strategic autonomy, forging a new battery industry blueprint for a sustainable future.

About ProLogium :

Founded in 2006, ProLogium Technology is an energy innovation company dedicated to the R&D and manufacturing of next-generation lithium ceramic batteries. The company holds nearly 1,000 patents globally (granted and pending). After introducing the world’s first next-gen battery with ceramic separators in 2013, ProLogium has been at the forefront of the battery technology. In 2025, ProLogium once again leading the industry by launching the world’s first Superfluidized Inorganic Solid-State Electrolyte Battery.

ProLogium’s first Giga-level Factory in Taoyuan, Taiwan came online in 2024 to supply the global market. In 2024, the company achieved US$5.3 million in revenue, representing 134% year-over-year growth, a testimony of its technology readiness and mass production capability. n May 2024, ProLogium officially announced the opening of its first overseas R&D center in Paris-Saclay, France, providing localized solutions for the European market. Later that year, its first overseas Giga Factory project, located in Dunkirk, France, received both environmental and construction permits. The groundbreaking scheduled is scheduled for 2026 and the Gigafactory is expected to come online in 2028.