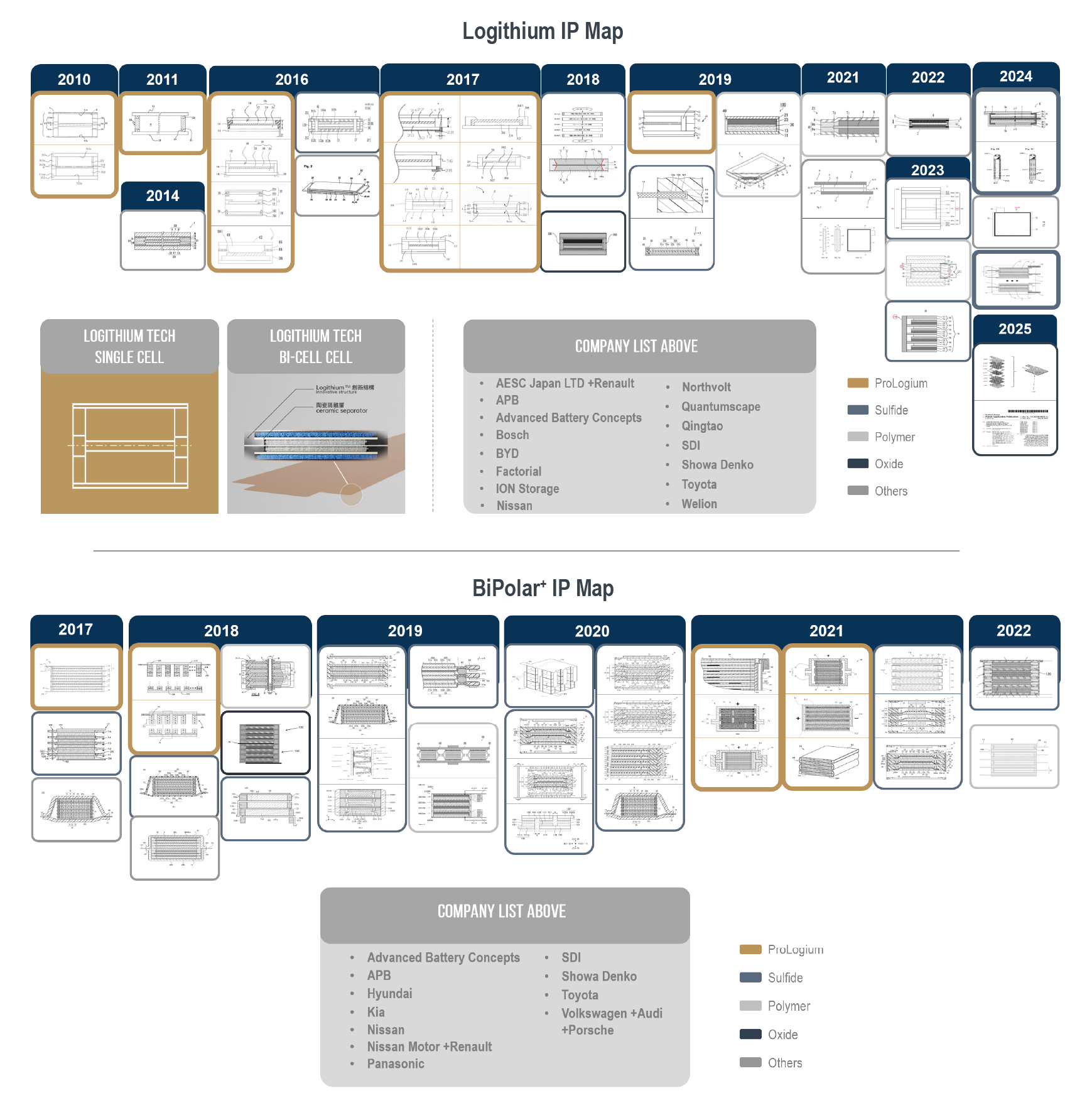

Solid Technical Moat

Solid Technical Moat

years of R&D

patents

engineers

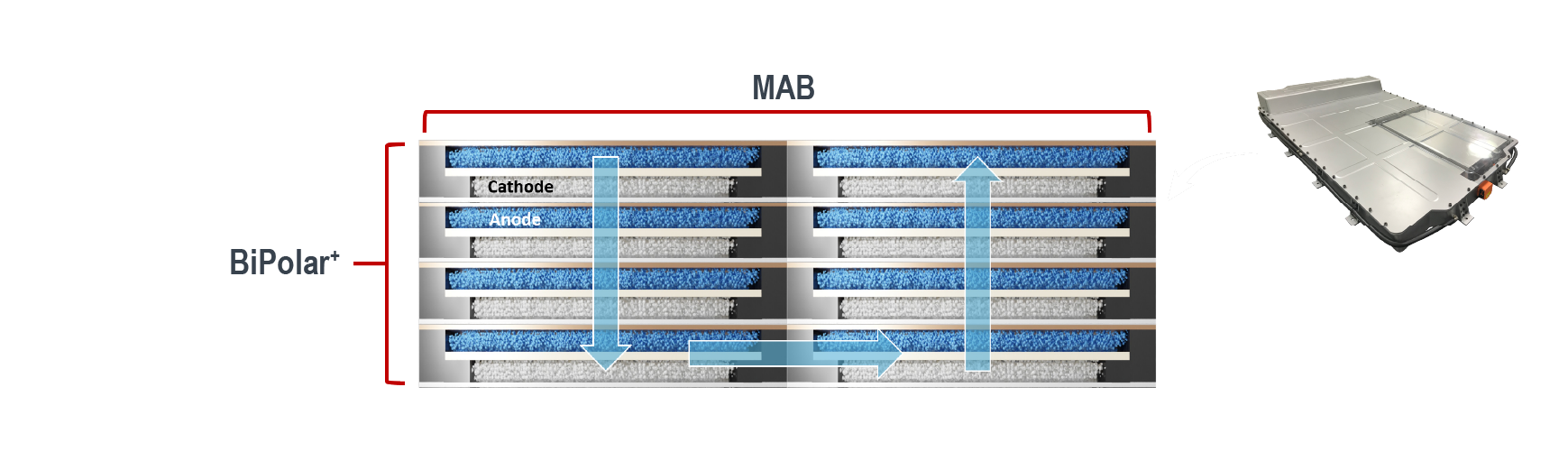

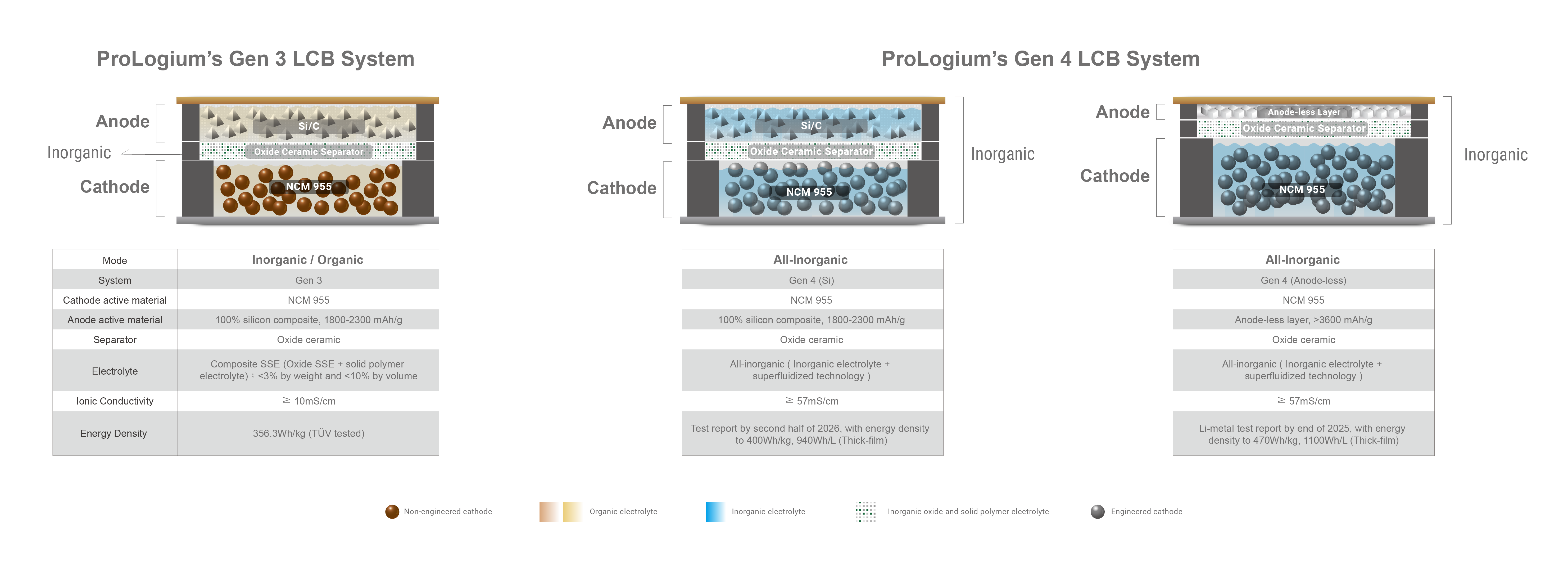

ProLogium’s Next Generation LCB System

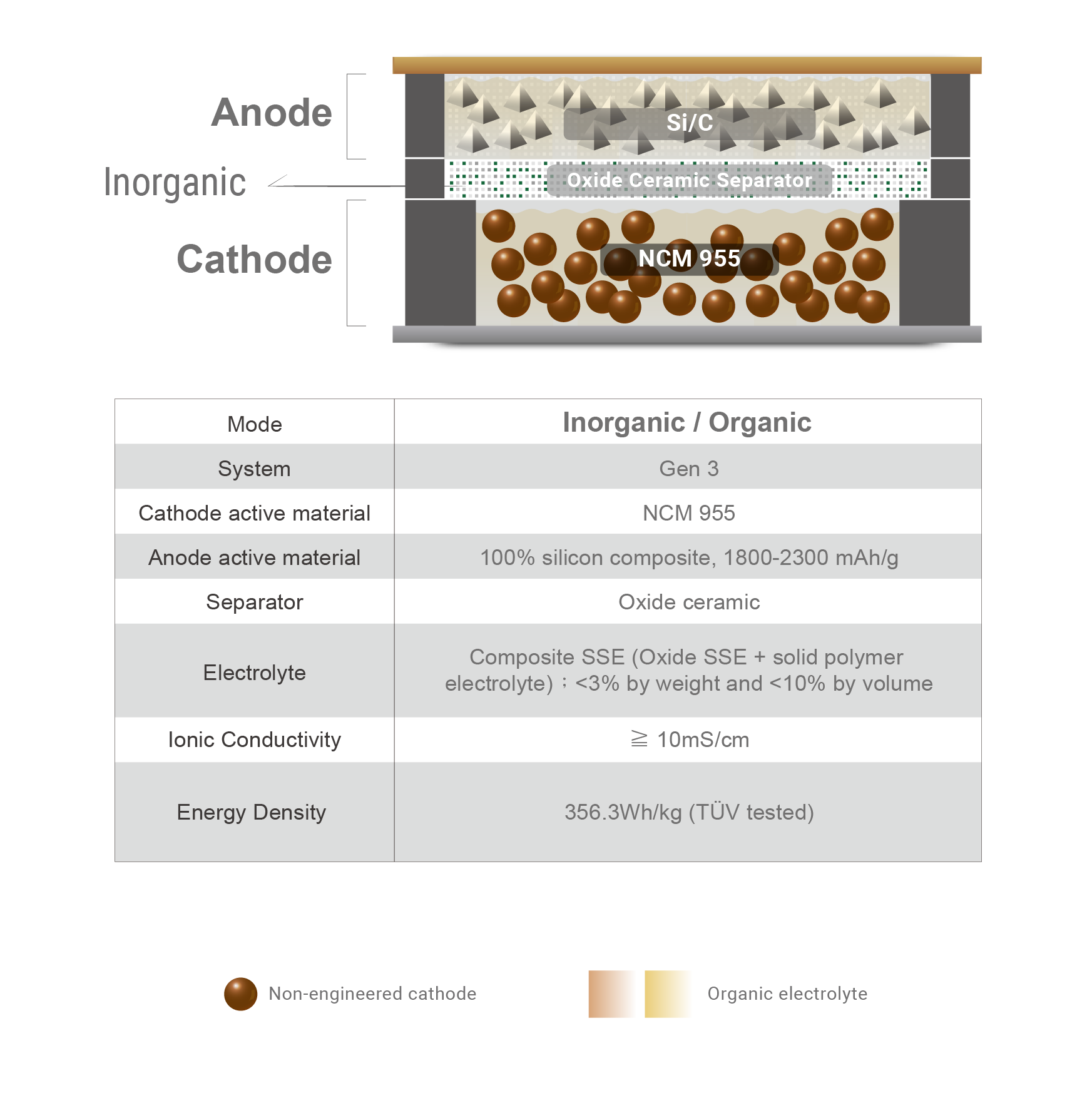

ProLogium’s Gen 3 LCB System

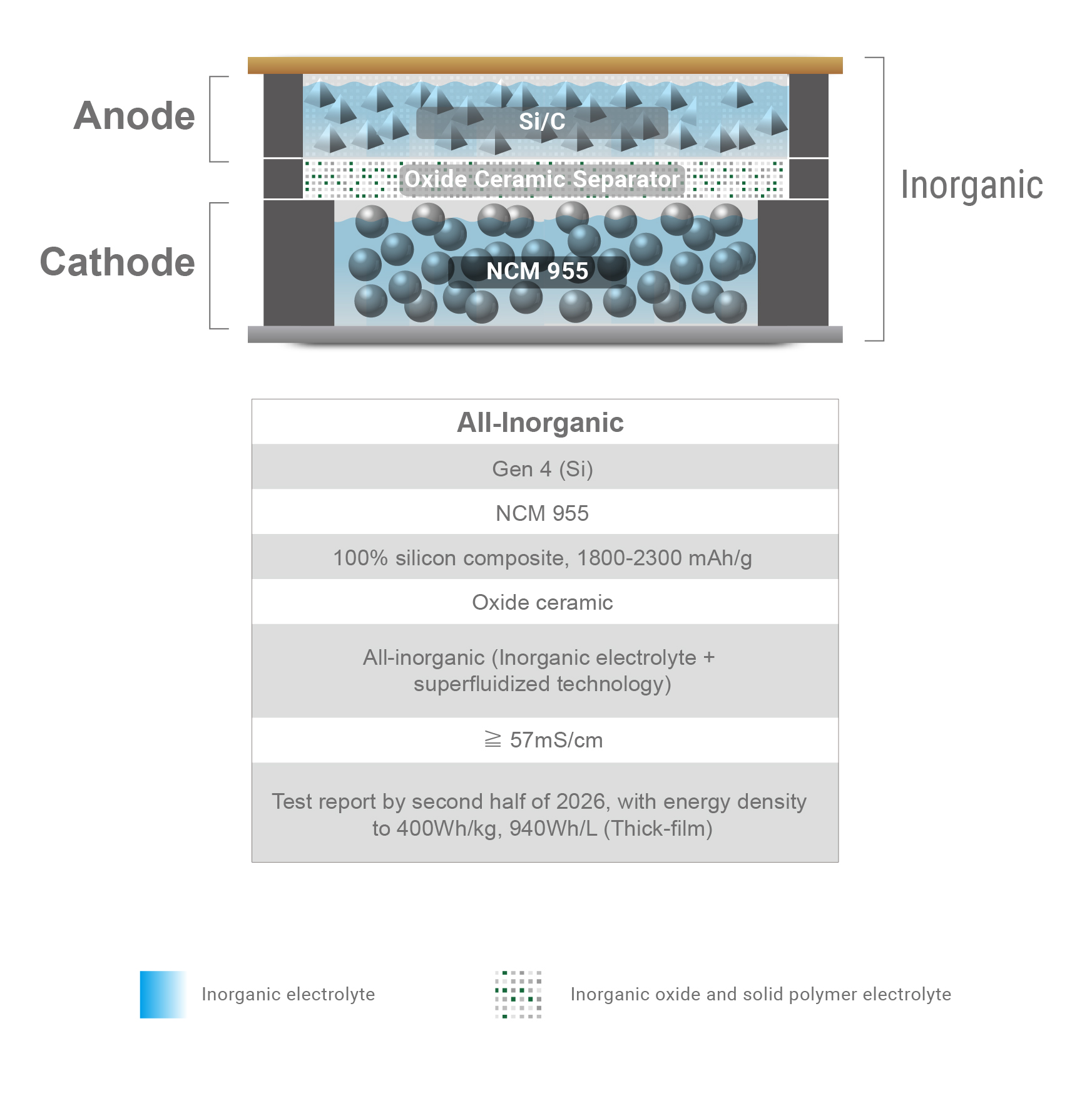

ProLogium’s Gen 4 LCB System

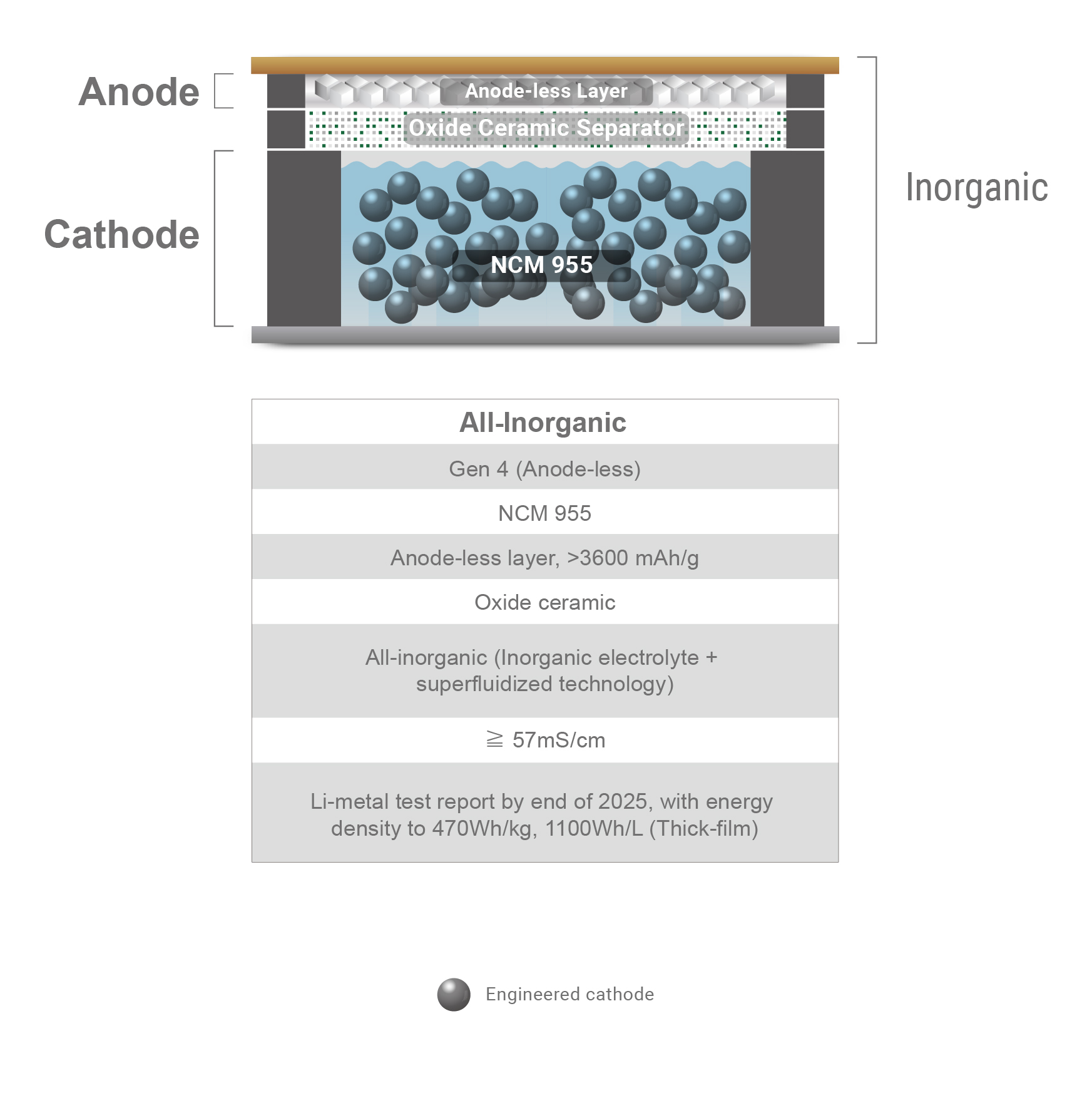

ProLogium’s Gen 4 LCB System

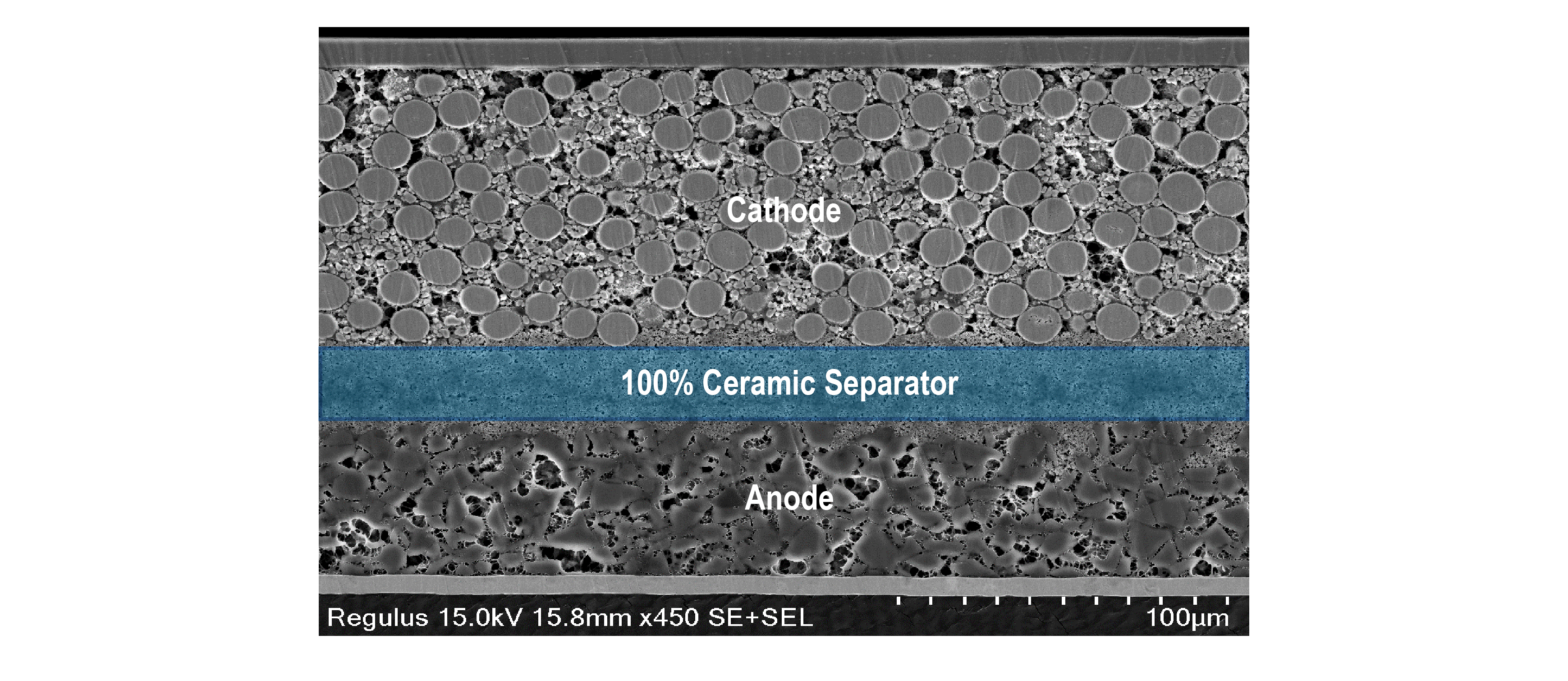

100% Ceramic Separator Intrinsically Safe Structure with Solid Stability

100% Ceramic Separator

Intrinsically Safe Structure with Solid Stability

Solving conductivity and brittle issues of oxide electrolyte.

The all-ceramic separator, made from non-flammable inorganic oxides, offers intrinsic safety and exceptional structural robustness. This technology serves as a foundational pillar in our long-term technical development strategy, ensuring that all our innovations achieve maximum performance while maintaining robust safety standards. This innovation has been patented since 2012.

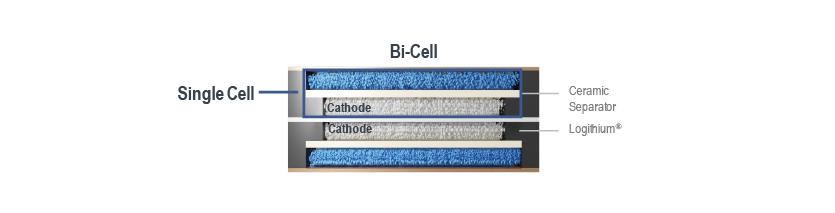

Components of LCB technology

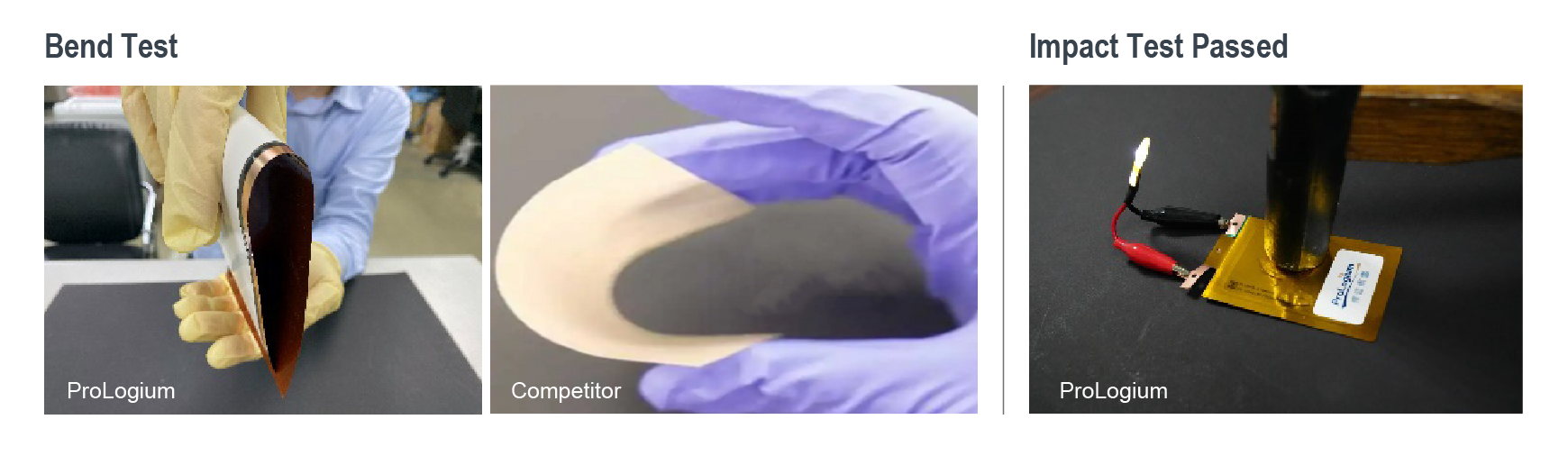

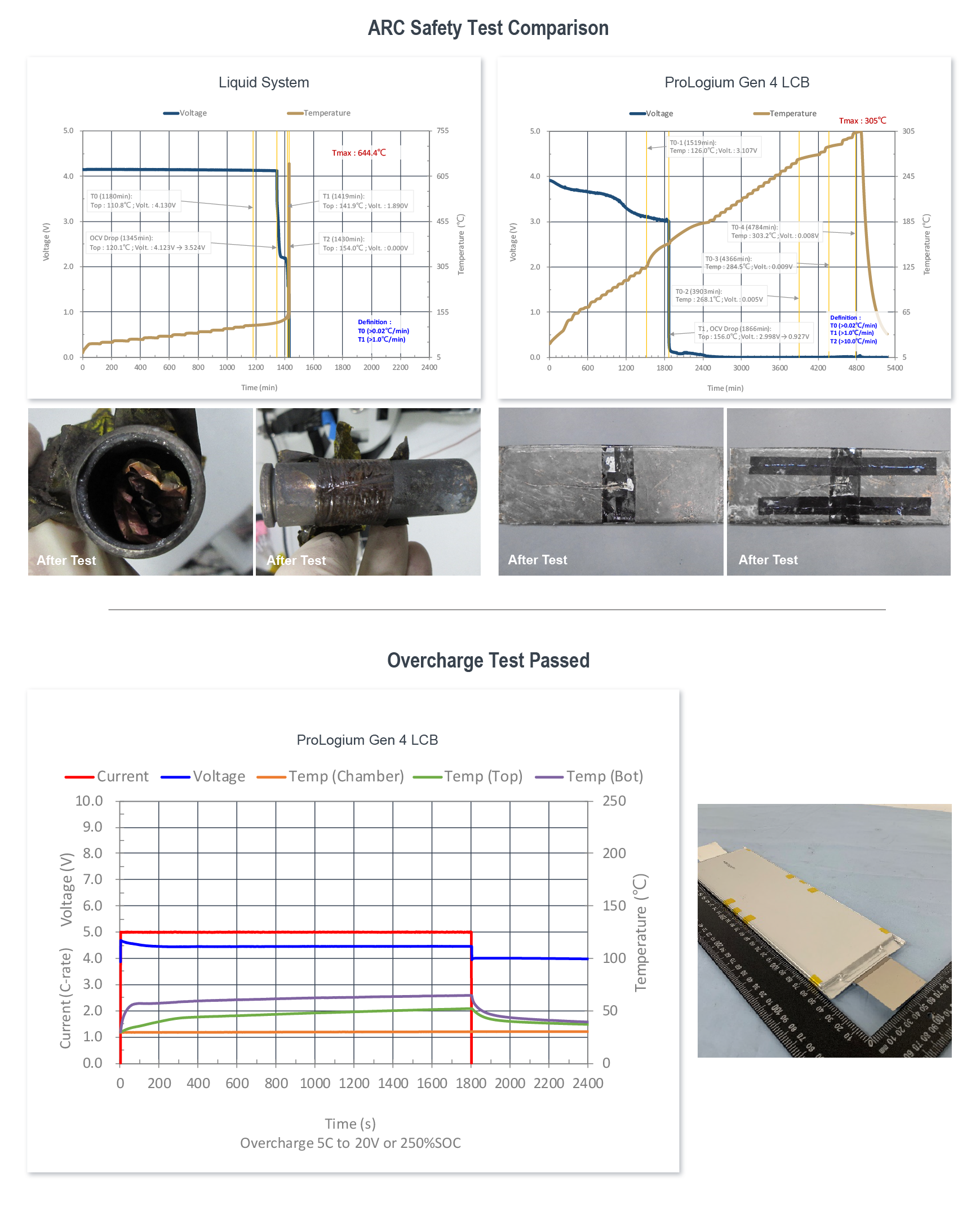

Structural robustness

The all-ceramic separator delivers exceptional mechanical stability and incompressibility. It remains unaffected by the internal stresses caused by electrode swelling and contraction during charge–discharge cycles, while also withstanding external physical impacts to prevent structural damage. By effectively blocking short circuits and thermal runaway, it significantly enhances battery durability under both external forces and long-term operation, providing the highest level of safety protection across diverse application scenarios.

Outstanding thermal stability

The all-ceramic separator exhibits exceptional thermal stability, maintaining structural integrity even at decomposition temperatures above 1000°C and retaining electrical insulation at 300°C, demonstrating its intrinsic safety properties. It is suitable for various applications under extreme temperature conditions, significantly reducing the risk of thermal runaway.

In addition, compared to conventional materials, the all-ceramic separator offers three times higher thermal conductivity, enhancing internal heat dissipation. This effectively accelerates heat transfer and release, ensuring internal thermal stability even under high-power operation, thereby improving battery safety and cycle life during charge–discharge cycles.

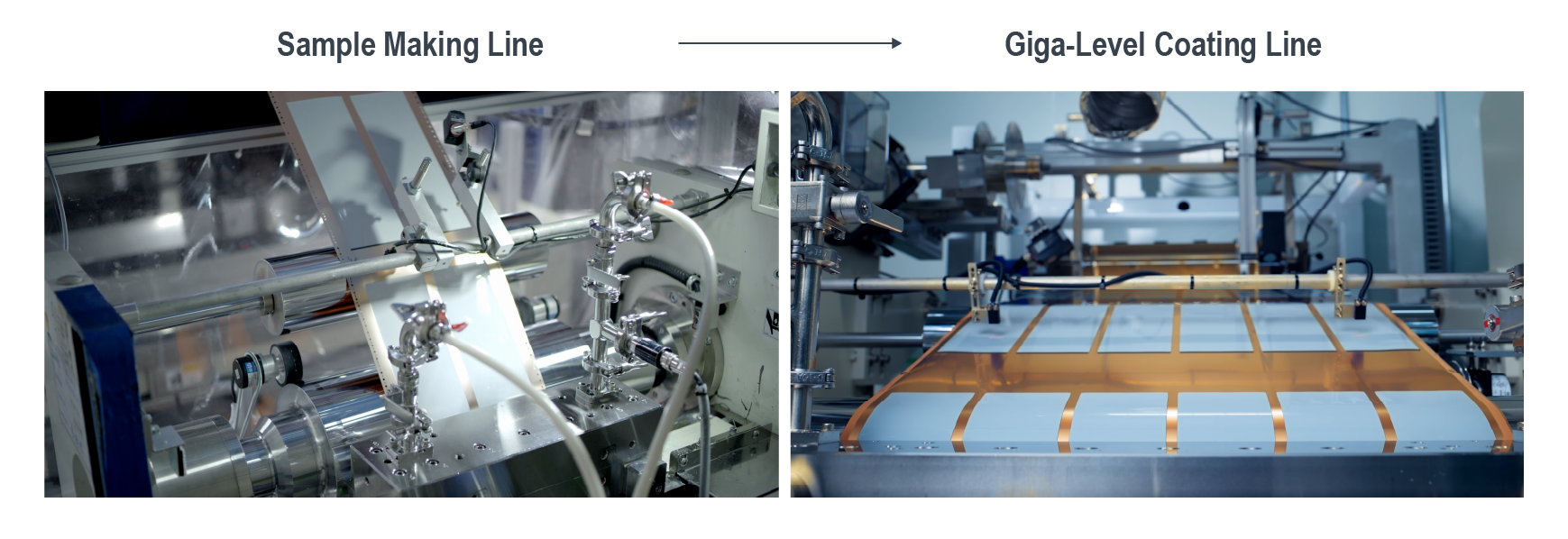

Overcoming roll-to-roll barriers for rapid mass production

Continuing ProLogium’s long-standing R&D spirit of “producibility”: developing a roll-to-roll process for inherently rigid ceramic materials is a proprietary manufacturing achievement we take pride in.

Since 2013, our Sample Making Line has prepared ceramic separators via coating instead of sintering, offering significantly greater feasibility for mass production and higher throughput. In 2017, ProLogium completed a full roll-to-roll pilot line, achieving coating speeds exceeding 12 m/min. The GWh-level production line, launched in 2024, increases the ceramic separator coating speed to 30 m/min, enabling dual-layer coating to simultaneously apply the electrode slurry and the ceramic separator, further enhancing production efficiency. Production speed is expected to reach 55 m/min by 2026.

Superfluidized All Inorganic Solid-State Electrolyte

Intrinsically Safe Material Synthesized from ASM

Superfluidized All Inorganic

Solid-State Electrolyte

Intrinsically Safe Material Synthesized from ASM

Active safety mechanism going beyond intrinsic safety.

The superfluidized all-inorganic solid-state electrolyte represents the ultimate generation of next-generation lithium-ceramic batteries, delivering comprehensive safety, high energy density, fast-charging capability, long cycle life, low-temperature stability, high-value recyclability and cost-effective commercial viability.

Multifaceted Security:

• Intrinsic Safety

The superfluidized all-inorganic solid-state electrolyte is intrinsically non-flammable. Even under high-temperature and high-voltage conditions, it does not generate combustible or toxic gases. Moreover, it prevents structural collapse of the battery and the formation of flammable materials at elevated temperatures, making it a truly intrinsically safe material.

By contrast, the sulfide-based solid-state electrolyte releases highly flammable sulfur vapors in high-temperature oxidative environments, leading to spontaneous combustion. Furthermore, when subjected to external mechanical damage, its stable ground-state lithium ions can be converted into excited-state lithium radicals, which act as flammable species under heat. Therefore, sulfide electrolytes cannot be considered intrinsically safe materials.

• Active Safety

The superfluidized all-inorganic solid-state electrolyte itself serves as an Active Safety Mechanism, composed of ASM components. When exposed to high temperature and high voltage conditions, it automatically decomposes into ASM components, autonomously stabilizing the cathode crystal structure to prevent its high-temperature collapse that would generate oxygen and heat. Meanwhile, at the anode, it transitions the electrode from an excited state to a ground state, effectively blocking thermal runaway occurrence and providing active safety characteristics.

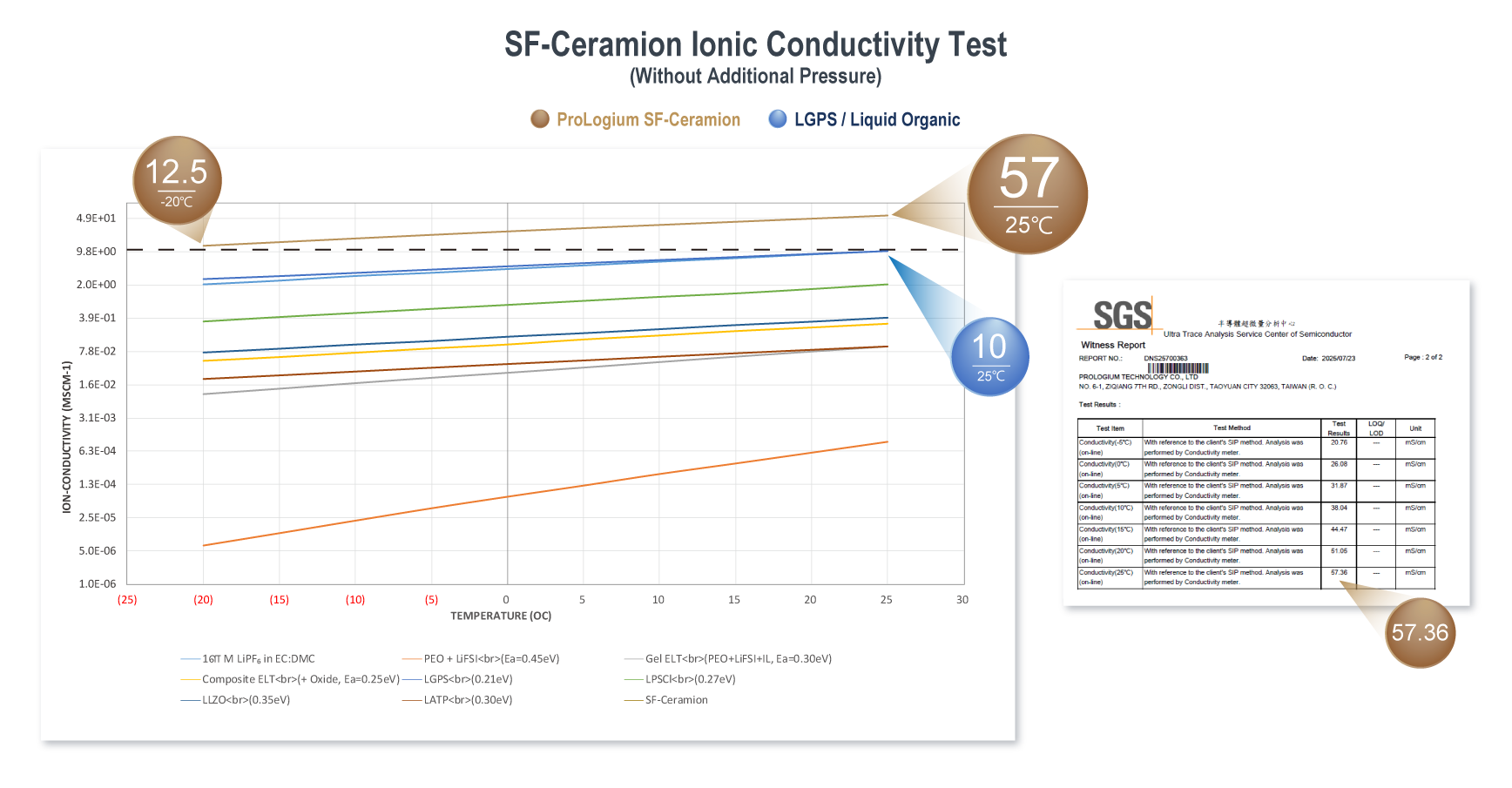

High Ionic Conductivity & Excellent Interfacial Contact

ProLogium’s superfluidized all-Inorganic solid-state electrolyte has been verified by SGS to achieve the world’s highest room-temperature ionic conductivity of 57 mS/cm at 25°C, 5 to 6 times higher than conventional liquid electrolytes and sulfide solid-state electrolytes. Even under extreme low-temperature conditions of –20°C, it still outperforms the room-temperature ionic conductivity of sulfide solid-state electrolytes and liquid electrolytes, maintaining 2–3x conductivity advantage and 90–95% discharge efficiency. In contrast, traditional batteries typically suffer 50–60% performance decay at low temperatures. This breakthrough electrolyte technology overcomes such limitations, delivering superior reliability and stability in extreme climates.

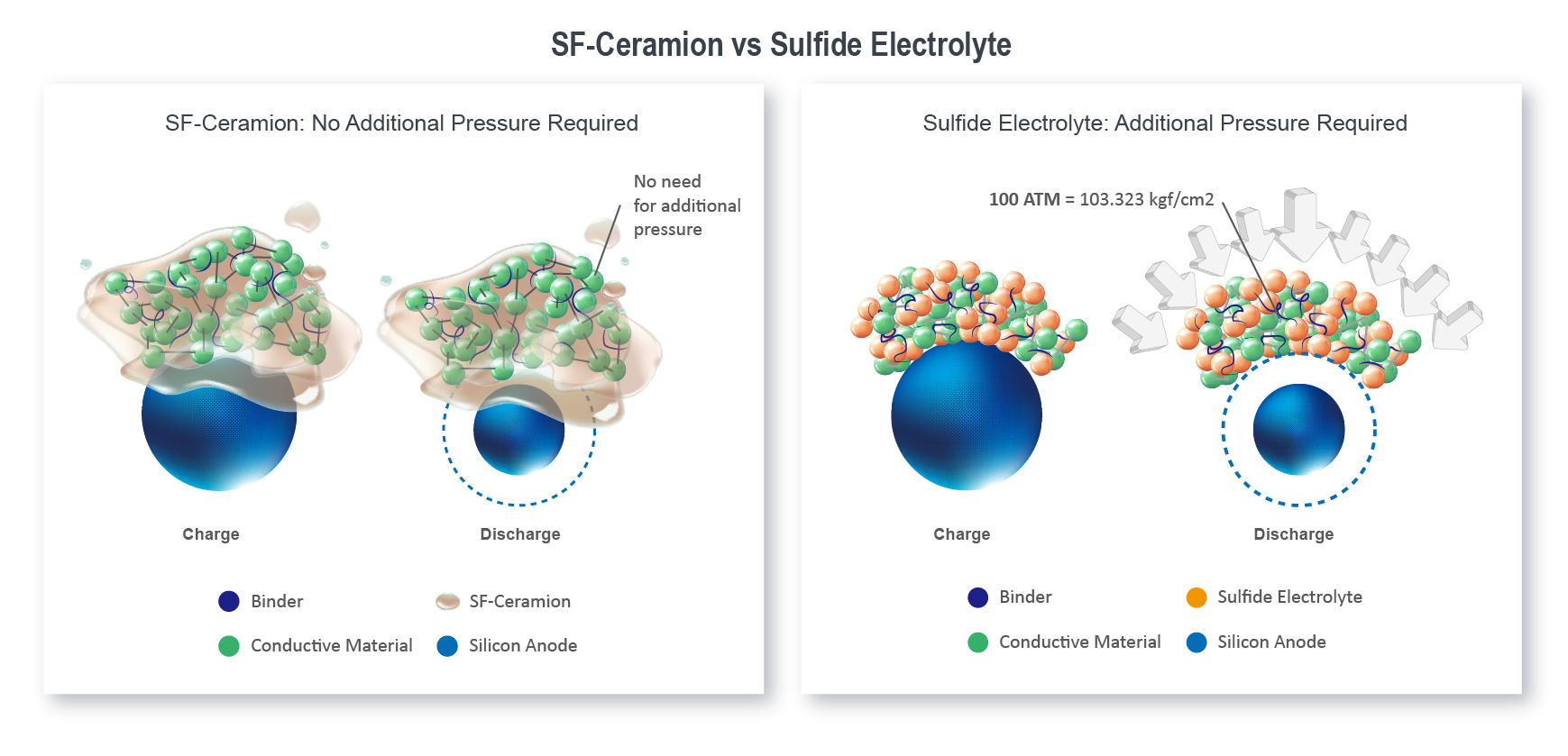

The high-conductivity superfluidized all-inorganic solid-state electrolyte, combined with ProLogium’s 100% ceramic separator (one of our three core technologies), resolves the potential swelling issues associated with using 100% composite silicon anodes. Without requiring additional pressure, it successfully enhances interfacial contact between the electrolyte and active materials, ensuring uniform and stable reactions between materials. This far exceeds sulfide solid-state batteries that require enormous pressure coefficients (100 ATM) to operate normally.

Cost Advantage

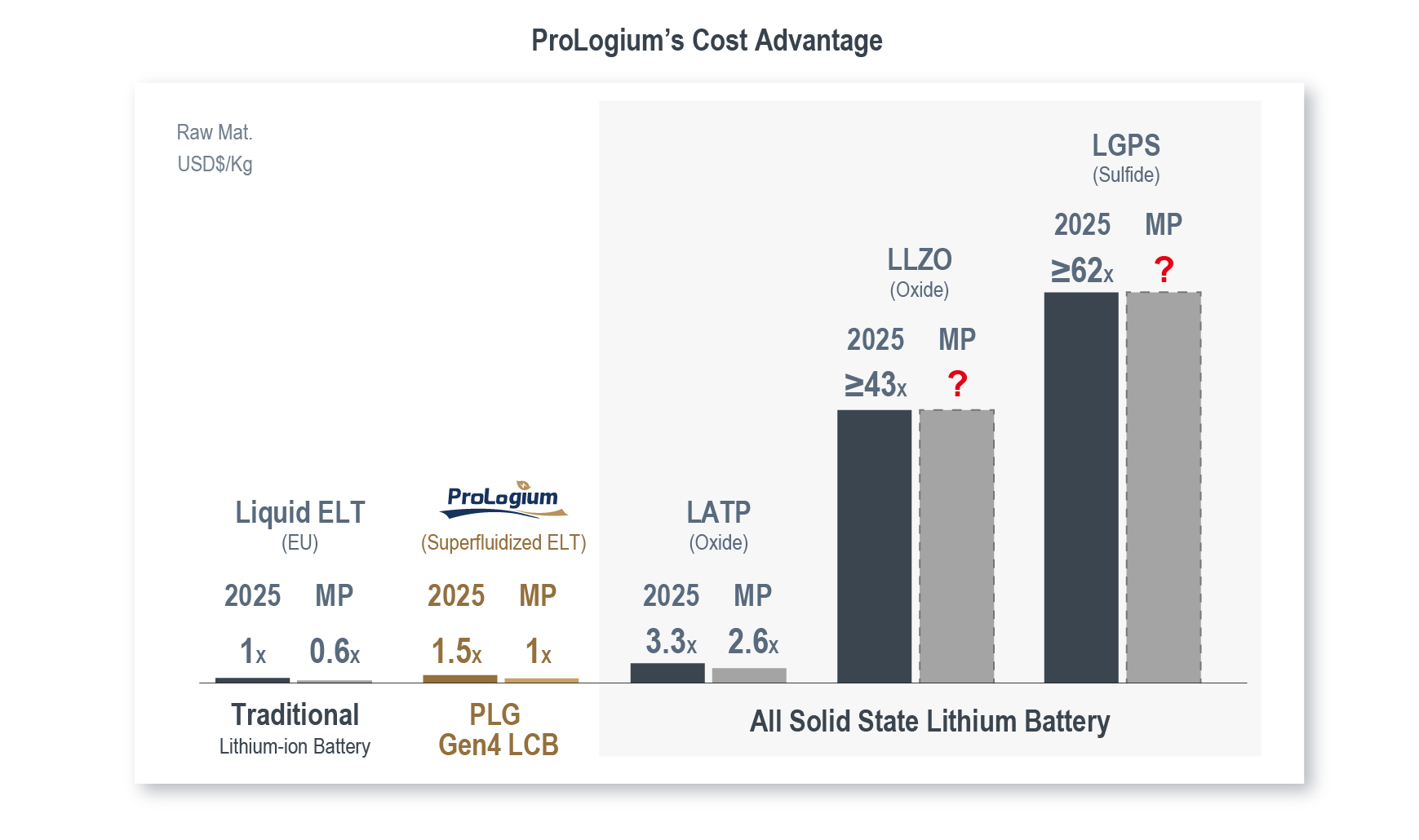

The development of SF-Ceramion (Superfluidized All-Inorganic Solid-State Electrolyte) technology prioritizes mass production feasibility as its core principle, selecting routes that use no rare elements and relatively simple material synthesis. Currently, the material synthesis cost in ProLogium’s laboratory has approached the level of existing liquid electrolytes. As stable scaled production advances, costs are expected to decrease further to match liquid electrolytes. Leveraging strategic partnerships with large chemical plants and economies of scale for procurement negotiations in the future will potentially further optimize the overall cost structure and strengthen commercial competitiveness.

In contrast, mainstream solid-state electrolytes in the market, such as LLZO (requiring rare element Lanthanum) or LGPS (requiring rare element Germanium), show limited cost reduction potential through scaling. Even LATP, while more cost-efficient, still cannot approach the cost level of liquid electrolytes.

ProLogium’s superfluidized all-inorganic solid-state electrolyte is inherently non-flammable and does not generate combustible substances, therefore eliminating the need for dry room environments throughout the production process. According to research reports from renowned Chinese securities firms, sulfide solid-state battery production lines require dry room Dew points twice as stringent as ProLogium’s 4th battery production lines (-80°C vs. -40°C), while dry room space requirements are 8-12 times larger than ProLogium’s 4th battery production lines. Furthermore, the downstream production of ProLogium’s Gen 4 batteries does not require 100MPa additional pressure during stacking. These advantages significantly reduce both CAPEX and OPEX for ProLogium’s 4th battery manufacturing. The simplified manufacturing process further ensures producibility and economic viability for future large-scale mass production.

100% Silicon Composite Anode

Perfect Balance between High Performance and Low Cost

100% Silicon Composite Anode

Perfect Balance between High Performance and Low Cost

Higher assembly efficiency, longer range.

The 100% composite silicon anode combines four key advantages: high energy density, ultra-fast charging capability, lightweight design, and cost efficiency. Leveraging our proprietary cell architecture technology, it effectively mitigates the intrinsic swelling tendency of silicon-based materials, thereby maximizing material energy utilization.

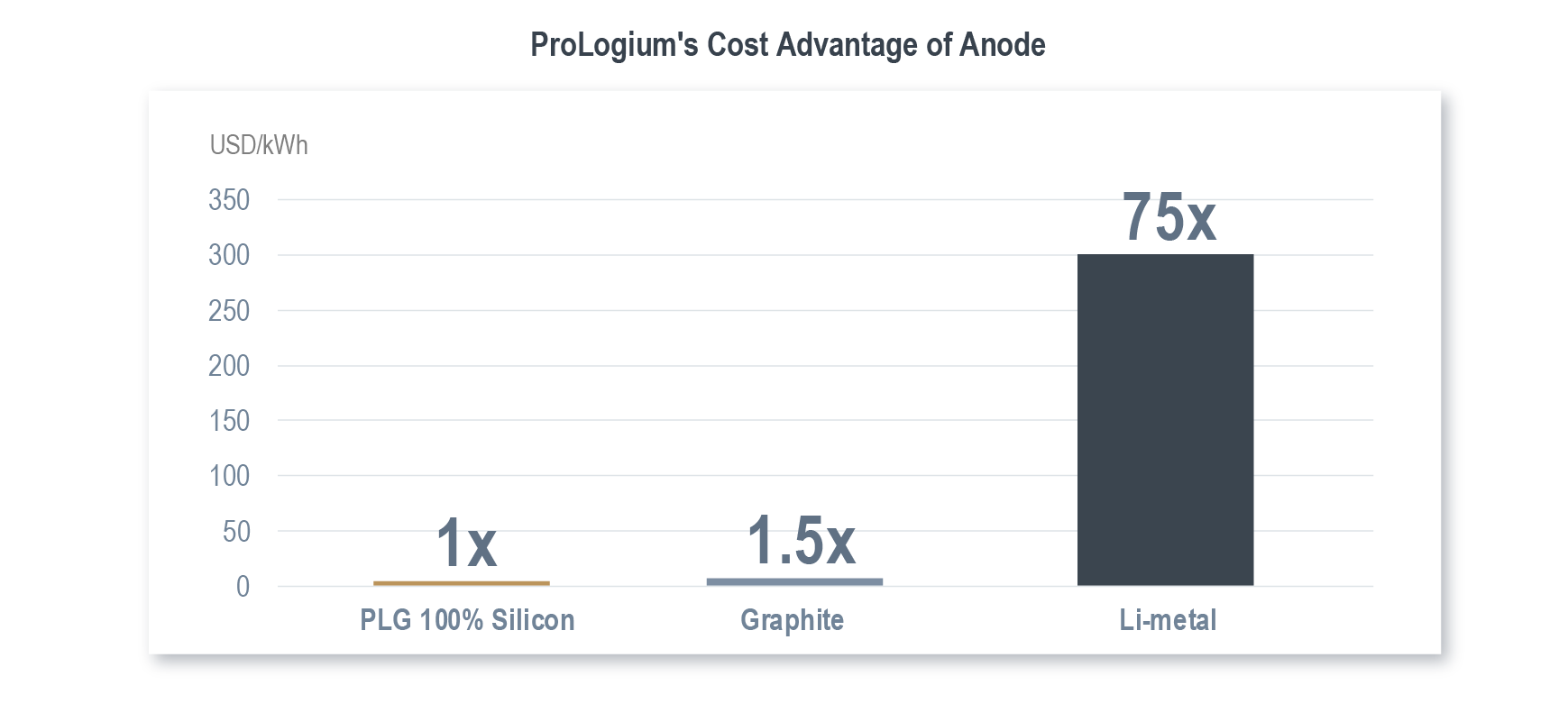

High energy density & cost efficiency

The 100% composite silicon anode achieves a high activation utilization of 1,800–2,300 mAh/g, nearly six times that of conventional graphite anodes (~360 mAh/g), while requiring only one-fifth of its thickness. It delivers an energy density of 380–400 Wh/kg and 900–940 Wh/L, while significantly reducing the unit energy cost to around two-thirds that of graphite (USD/kWh).

This cost advantage, compared with the consistently high price of lithium metal, further highlights the mass production feasibility of ProLogium’s Gen 4 battery in the next-generation battery landscape.

Ultra-fast charging performance

Graphite anodes rely on lithium-ion intercalation and deintercalation during charge and discharge. This process can easily disrupt the surface structure, and with increasing cycle numbers, localized stress at the graphite edge leads to C–C bond breakage, resulting in irreversible capacity loss.

In contrast, silicon naturally forms alloying reactions with lithium. Each silicon atom can bond with multiple lithium ions to form Li–Si alloys, significantly boosting specific capacity while enabling high-rate fast charging.

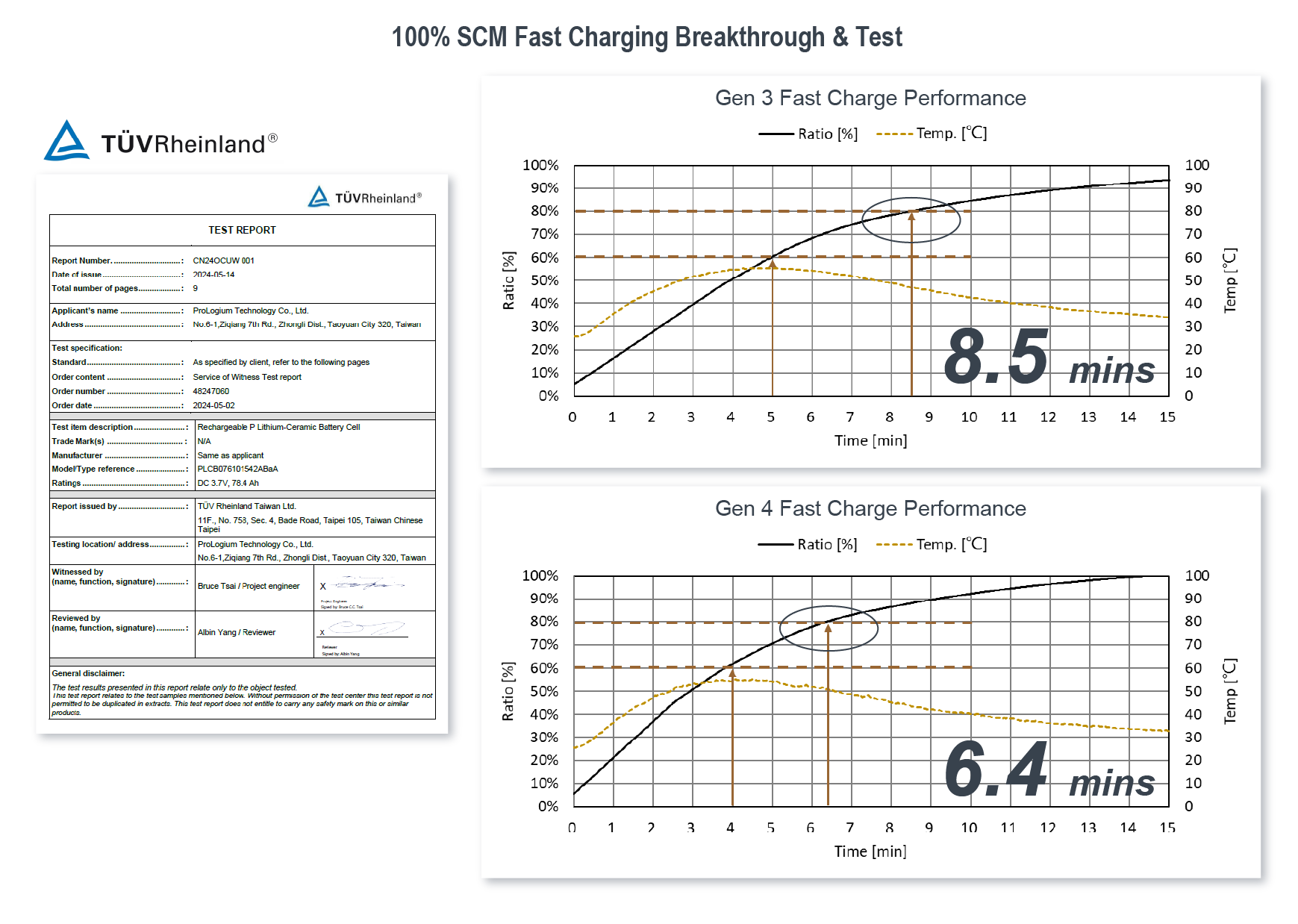

Leveraging this advantage, our Gen 3 and Gen 4 batteries achieve industry-leading fast charging without the need for additional pressure. Under a 400V system design, our Gen 3 battery can reach 80% of charge in just 8.5 minutes, while our Gen 4 battery’s charging window is further reduced to 6.4 minutes. Within the 10–80% charging window, our battery’s cycle life exceeds 1,200 cycles.

By comparison, recent discussions around “flash charging” at 1,500V face practical and safety limitations, as today’s charging infrastructure and module components are not designed for such high voltages and charging at these levels introduces extremely safety risks.

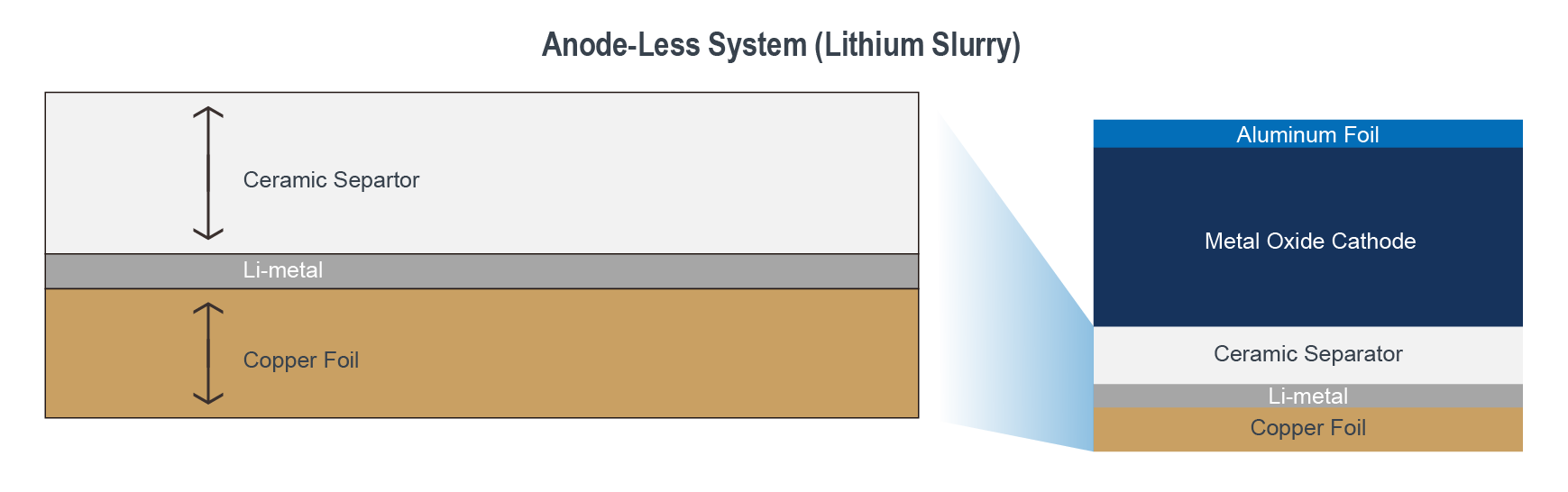

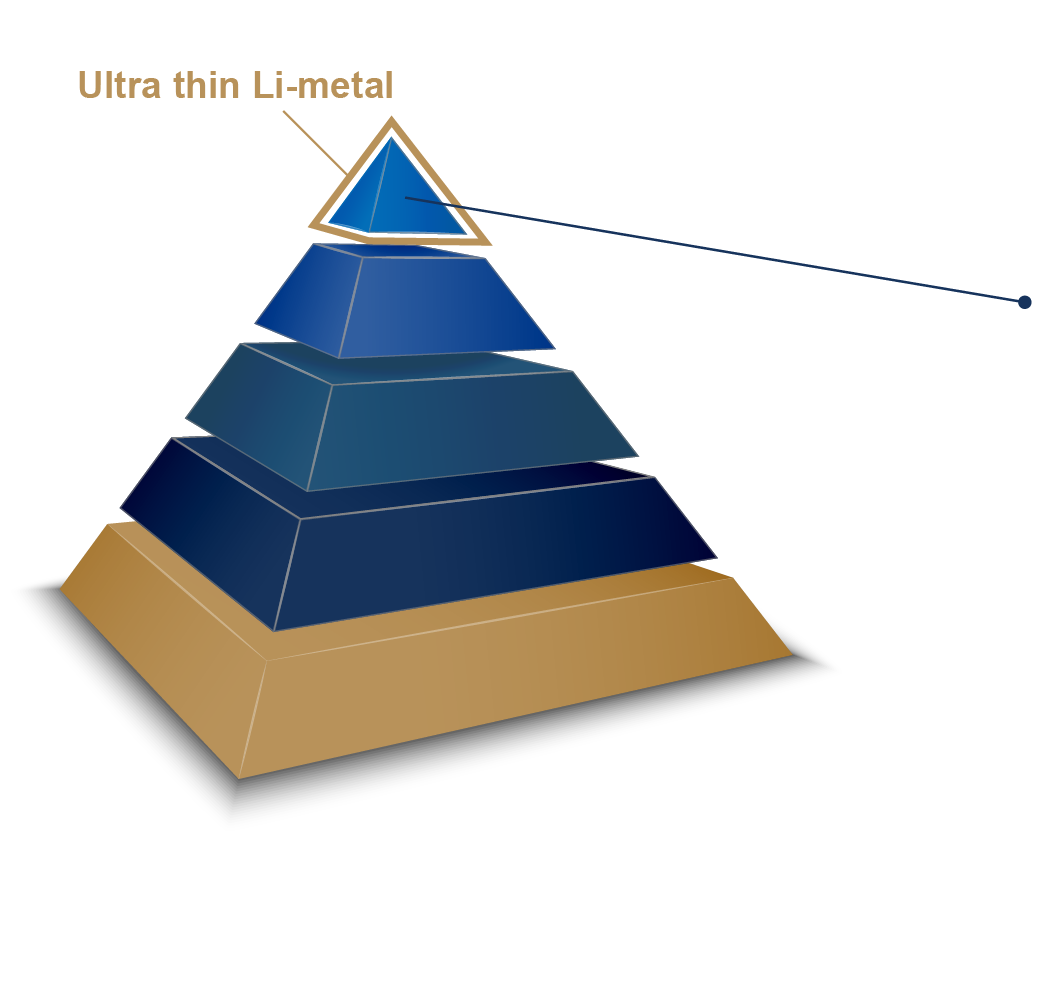

Anode-Less Ultra Thin Li-Metal

Anode-Less

Ultra Thin Li-Metal

Higher assembly efficiency, longer range.

Building on the intrinsic and active safety of our superfluidized all-inorganic solid-state electrolyte, ProLogium’s Gen 4 SF-Ceramion technology now enables anode-less architectures. By applying pattern coating technology to ultra-thin lithium metal foils, the cells can achieve an energy density of 430–470 Wh/kg and 1000–1100 Wh/L, while also supporting roll-to-roll high-throughput manufacturing with costs reduced to a level comparable to graphite anodes.

Although lithium metal offers extremely high energy density, its inherent instability and the risk of dendrite growth, which can pierce the separator and react with the cathode to trigger thermal runaway, remain the biggest obstacles to safe and stable application. ProLogium’s proprietary superfluidized all-inorganic solid-state electrolyte and all-ceramic separator structure effectively suppress dendrite penetration, unlocking the full potential of lithium metal for truly safe and efficient deployment.