Press Releases/ Announcement

A Hidden Hazard in Disguise of a Safety Mask? ProLogium Debunks the Solid-State Battery Safety Myth with Breakthrough Dual Protection “Intrinsic Non-Combustibility × Active Risk Mitigation” to Eliminate Thermal Runaway and Redefine the Safety Standard for Solid-State Lithium Batteries

Press Information

Aug 7, 2025

Lithium batteries should not be hidden bombs sitting in technology products. Rather, they must be reliable and controllable energy carriers. Against the backdrop of frequent fire incidents and in response to the growing pressure for electrification, ProLogium once again challenges industry misconceptions through technological evidence. Following the July launch of its fourth-generation superfluidized all inorganic solid-state lithium battery — featuring the world’s highest ionic conductivity and low-temperature adaptability, ProLogium now reveals another “Holy Grail” breakthrough of its t battery platform. The combination of intrinsically non-combustible materials and active thermal risk control, as verified by ARC (Accelerating Rate Calorimetry) testing and high-temperature flame simulations with gas torch, marks a new benchmark in lithium battery safety.

The Risk Has Never Gone Away: Four Decades, Sam Hazard

An Age-Old Problem: Why Are Lithium Batteries Still Unsafe?

Back in 1988, Moli Energy introduced the world’s first lithium metal battery using MoS₂ cathodes. However, lithium dendrite penetration caused internal short circuits and explosions, leading to a full product recall within a year. In 1991, Sony replaced lithium metal with carbon-based anodes, significantly reducing dendrite risks and ushering in the commercial era of lithium-ion batteries.

Yet, as the market demands higher energy density and faster charging, the industry widely adopted high-nickel cathodes (such as NCM811/955) and highly reactive anodes (e.g.,silicon or lithium metal). These new materials may still trigger volatile reactions under high temperatures and the problem associated with thermal runaway remains unresolved. In fact, thermal runaway never happens by chance — it’s the outcome of material properties and structural design. Even without an open flame, batteries on their own can activate internal chain reactions that lead to explosions. Unlike gasoline cars that need external ignition, lithium batteries are active energy sources themselves. Therefore, it is imperative to reform the material composition and redesign the system in order to address this ever-daunting challenge of safety.

“All-Solid-State” ≠ Panacea: Sulfide Systems Still Face Thermal Risk

Unless a solid-state battery system establishes intrinsic chemical stability, the label “all-solid-state” offers no guarantee of safety. Many so-called semi-solid-state or gel-type solutions still retain organic electrolytes and thermal triggers. The mere rebranding does not eliminate the risks. True safety is not defined by the term “solid state”, but by whether the system integrates material-level thermal stability and structural control. Otherwise, any “solid-state” technology could be a ticking time bomb wrapped in a safety label.

Today, the industry broadly recognizes fully inorganic solid-state electrolytes and all-ceramic separators as the two critical elements to solving thermal runaway issues. All-ceramic separators have been proven effective in real-world applications and generally considered the cornerstone of a safe battery architecture because they offer excellent thermal stability and electrical isolation, block dendrite penetration, and prevent thermal propagation.

However, the most closely watched “all-solid-state” technology — sulfide-based systems — still harbor significant risks due to the nature of materials. While sulfides offer structural deformability and favorable interface contact to enhance energy density, they may release flammable sulfur gases (S) and toxic hydrogen sulfide (H₂S) under high voltages and high temperatures. These gases can further react violently with lithium metal anodes, triggering thermal chain reactions and secondary combustion. Such reactions may even form lithium free radicals and resulting volatile phenomena such as explosions and magenta flames

Importantly, these thermal reactions are not related to dendrites, but rather self-ignition under extreme conditions due to inherent instability of the materials. When the electrolyte itself becomes an active heat source, the so-called “solid-state safety” becomes an illusion. Unless intrinsic reaction control mechanisms are embedded at the material level, even an “all-solid-state” battery may remain dangerously uncontrollable.

Even more concerning, semi-solid and gel-type designs — still common in the market — retain large amounts of organic electrolyte and harbor the same thermal hazards. These are merely cosmetic repackaging and g the fundamental risks are unchanged.

We must confront a key question:

Real battery safety is never a promise that the term “solid-state” can afford to guarantee. Only by integrating material-level and chemical-system stability with active thermal control can we establish a truly safe next-generation battery standard. Otherwise, the so-called “all-solid-state” systems without intrinsic safety and active protection may be nothing more than unexploded bombs in disguise.

A Safe Label Shattered: Sulfides Expose the Hidden Threat of Lithium Combustion

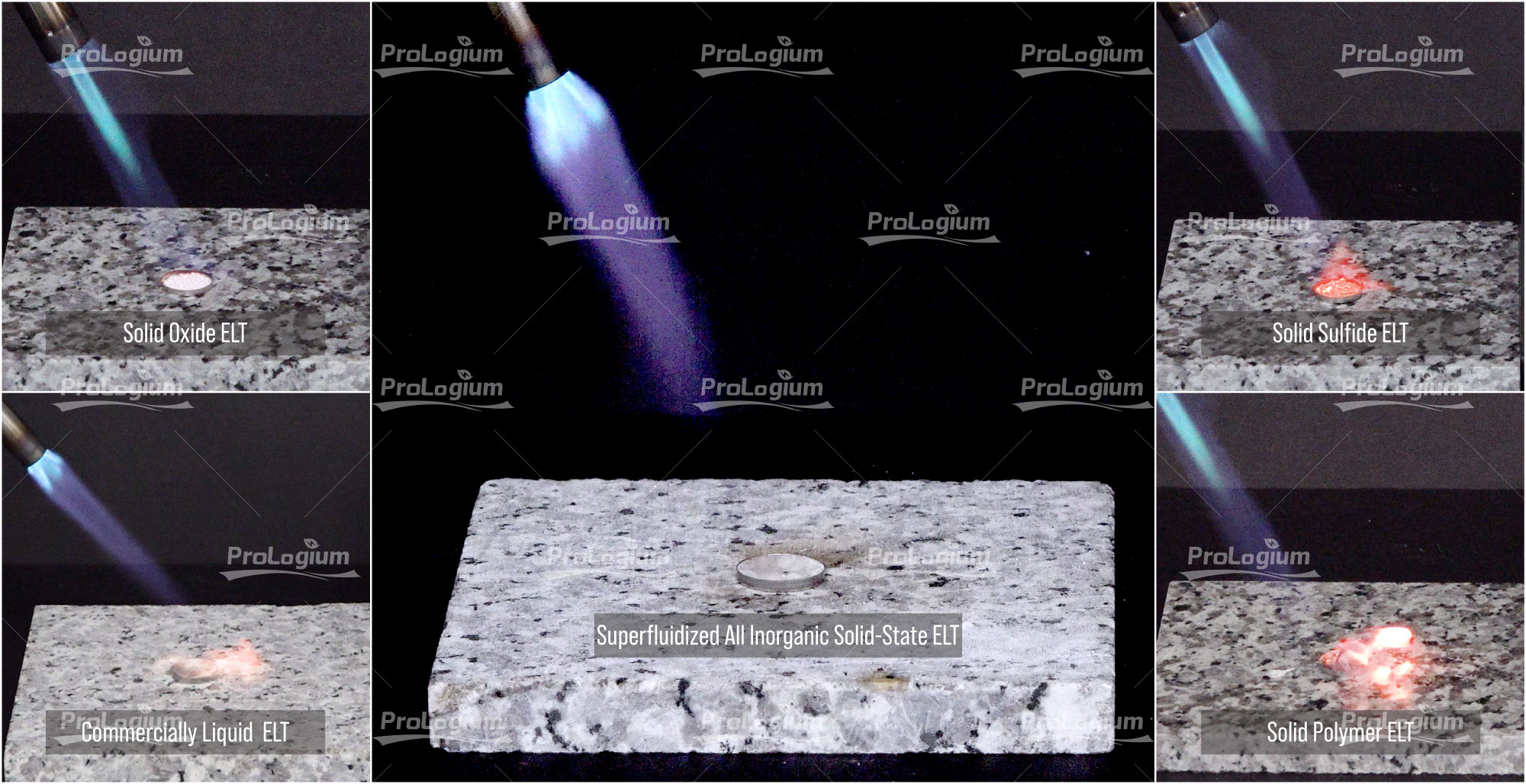

Sulfide solid-state electrolytes have been widely regarded as one of the key materials to enabling all-solid-state batteries due to their flexibility and malleability. However, their hidden chemical risks are revealed by ProLogium’s 900–1300°C high-temperature simulation tests. In the experiment: sulfides emitted purple-blue flames (sulfur) and light-blue flames (hydrogen sulfide), ultimately turning into a vivid magenta flame — the signature of lithium metal combustion.

This highlights a critical threat: Even without dendrite penetration, sulfide systems can transform into internal lithium-based explosives under heat, trigger thermal chain reactions, and cause intense burning, and potential explosions. This complex combustion behavior exposes the lack of intrinsic safety under extreme conditions — a red flag that must be acknowledged across the battery value chain.

In contrast, ProLogium’s fourth-generation battery — featuring an oxide-based all ceramic separator and superfluidized all inorganic solid-state electrolyte — showed no visible combustion under the same high-temperature conditions and demonstrated its truly non-flammable nature residing in materials.

These findings once again affirm a crucial truth: “Solid-state” is by no means a safety guarantee. Only through material-level design and reaction control can a genuinely safe and controllable battery platform be achieved.

Not all “solid-state” batteries are safe — High-temperature combustion tests reveal intrinsic material risks

- Under intense flame, solid-state sulfide electrolytes emit a vivid magenta flame, a warning sign of a lithium metal combustion reaction and the likelihood of developing into —”built-in lithium explosives” under thermal disturbance.

- Solid polymer electrolytes ignite directly with intense flames, while off-the-shelf liquid electrolytes release bright orange flames. Both outcomes reveal the flammability of their hydrocarbon-based components and a lack of resistance to thermal hazards.

- Only oxide-based all ceramic materials and superfluidized all inorganic solid-state electrolytes remain flame-free throughout the test and show no visible changes in appearance or structure before and after combustion — demonstrating truly intrinsic non-combustibility and exceptional thermal stability.

True Threat Resides Not Only in Electrolytes — But in Active Materials (Cathodes and Anodes)

The root cause of lithium battery thermal runaway is the inherent reactivity of the electrodes under high temperatures. The cathode can release active oxygen, while the anode is highly reductive. When these reactive materials interact, they can trigger a chain exothermic reaction and may even self-ignite or explode without external fire. These risks have not been eliminated — they’ve simply been stacked up through decades of material and structural design.

ProLogium redefines this risk logic by establishing a “Dual Safety Architecture” as the new standard that delivers intrinsic stability before danger unfolds.

- All-ceramic separator: This maintains mechanical integrity and insulation under high temperatures and effectively blocks lithium dendrite penetration and thermal propagation.

- Superfluidized all inorganic solid-state electrolyte: A world-first electrolyte with inherent non-combustibility and built-in ASM (Active Safety Mechanism) that infiltrates electrodes and stabilizes internal reactions.

At the core of this breakthrough is ASM (Active Safety Mechanism), which addresses the root causes of thermal disasters by actively disarming the battery’s two major ignition points:

- Oxygen Locking: ASM stabilizes the cathode structure and suppresses the release of active oxygen.

- Lithium Taming: ASM neutralizes lithium’s high reactivity and fully inhibits the violent side reactions.

This is not just material innovation — it is a complete rethinking of safety logic in battery systems.

From Ignition Point to End Point — A Technological Reversal of Thermal Runaway

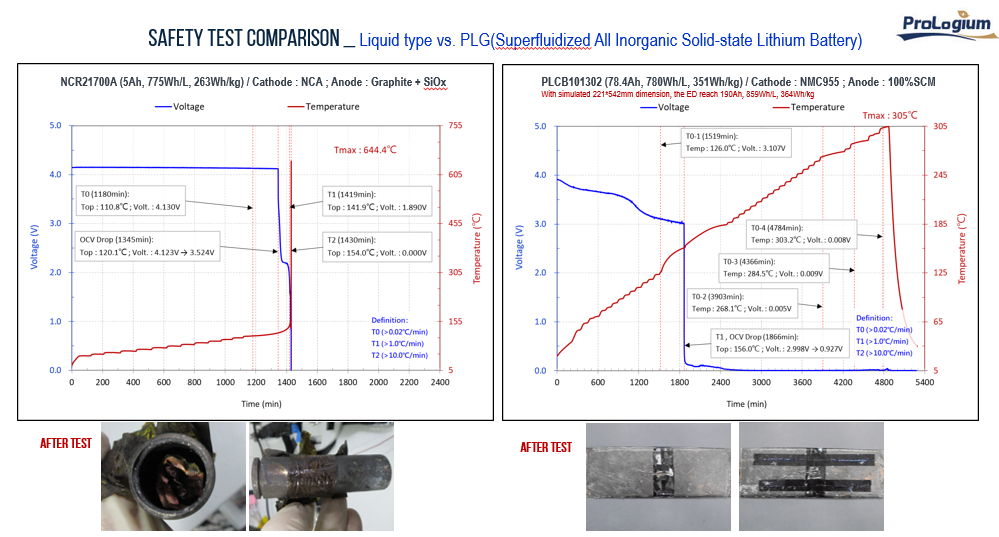

In ARC (Accelerating Rate Calorimetry) thermal testing, ProLogium’s fourth-generation superfluidized all inorganic solid-state electrolyte system demonstrated unprecedented thermal stability in lithium battery history: No thermal runaway, no spontaneous heat peaks, and significantly reduced total exothermic energy. The embedded ASM material activates at critical temperatures, prioritizing reactions with the cathode/anode reactants and interrupting the thermal chain reaction before it propagates.

This is more than just a material enhancement — it marks a technological leap and the first time ever since the invention of lithium batteries in the 1980s that hazardous reactions are proactively terminated at both the material level and the structural level. Even in the ultimate configurations consisting of NCM955 high-nickel cathodes and fully silicon-lithium alloy anodes, potential thermal reactions are suppressed by the proactive intervention of ASM, in order to prevent the cascading effects that lead to thermal runaway.

This holistic innovation — from material properties to chemical behavior and structural design — is leading lithium batteries into a new era of controllable safety.

ARC Test: ProLogium’s Gen 4 Battery Breaks the Thermal Reaction Chain

Accelerating Rate Calorimetry (ARC) tests reveal the stark contrast of heating curves between a traditional lithium battery and ProLogium’s fourth-generation solid-state battery. The traditional system progresses into thermal runaway, while ProLogium’s embedded ASM material automatically activates at critical temperatures, halting the propagation of side reactions and cutting off the thermal chain, effectively terminating a thermal disaster in the

Dual Protection of Battery Safety: From Stable Materials to Controlled Reactions

A decade of dedication has yielded a breakthrough that redefines the safety standard for lithium batteries.

After systematically examining the hidden risks of mainstream solid-state battery designs, ProLogium introduces its fourth-generation superfluidized all inorganic solid-state lithium battery solution — the world’s first to combine intrinsic non-combustibility and removal of hazard factors with an active safety mechanism based on materials and centered on reactions. This innovation shifts the safety paradigm of lithium batteries from passive containment to proactive risk elimination.

The technology is built on two cornerstone innovations:

- Oxide-based all-ceramic separator (in mass production since 2013) retains structure stability and electrical insulation at high temperatures, effectively blocking dendrite penetration and thermal propagation.

- Proprietary superfluidized fully inorganic solid-state electrolyte, now embedded with the ASM (Active Safety Mechanism) material — a proactive agent that directly interrupts the chain of hazardous reactions, serves more than just a passive medium and acts as an active defense against disasters.

This is more than material stacking — it is a redefinition of what a “safe battery” truly means:

From structural protection and material stability to reaction-level intervention, ProLogium’s approach builds a comprehensive system shelter against risk.

The Dawn of Controllable Risk: Redefining the Next Decade of Lithium Batteries

With its superfluidized all inorganic solid-state lithium battery, ProLogium officially launches the era of controllable risk in lithium battery technology.

This platform has been validated in ultimate configurations — combining NCM955 cathodes, full-silicon composite anodes, and embedded ASM — demonstrating that even under the most aggressive high-energy-density architectures, it can maintain operational stability and deliver system-level disaster prevention.

This marks the first time since the invention of lithium batteries in the 1980s that lithium batteries have been successfully transformed from a source of inherently active hazards to a carrier of controlled risks. In the same way as nitroglycerin needs to be combined with diatomaceous earth to form usable dynamite, the evolution towards true safety of lithium batteries must rely on the breakthrough of materials and system integration. For the first time in history, ProLogium has created a lithium battery system with its unique superfluidized all inorganic solid-state electrolyte, built-in ASM (Active Safety Mechanism) and all-ceramic separator, capable of proactively halting thermal chain reactions.

We believe that future energy systems must no longer compromise on risks. Rather, it should be designed from the source for intrinsic safety, active protection against disasters and feasibility for mass production. Driven by this belief, ProLogium will center on its fourth-generation platform to accelerate strategic alliances with global energy companies, material suppliers, and manufacturers — to establish the next-generation energy infrastructure and advance the electrification revolution into a new era of genuine safety

ProLogium’s ASM (Active Safety Mechanism) material has been awarded a bronze Edison Award in recognition of its groundbreaking innovation for critical energy infrastructure. Presented by the Edison Awards in the United States, this honor represents one of the highest global accolades for impactful technological inventions. The award highlights ProLogium’s international leadership in advancing intrinsic safety of lithium batteries through original material development and reaction-level design.

About ProLogium :

Founded in 2006, ProLogium Technology is an energy innovation company dedicated to the R&D and manufacturing of next-generation lithium ceramic batteries. Its proprietary technologies are protected by over a thousand global patents (granted and pending). After introducing the world’s first next-gen battery with 100% ceramic separators in 2013, ProLogium has been at the forefront of the battery technology. In 2025, ProLogium once again leads the industry by launching the world’s first Superfluidized all Inorganic Solid-State Lithium Battery. ProLogium’s Gigafactory in Taoyuan, Taiwan came online in 2024 and has shipped more than 500,000 battery cells over the period of one year and half to date. This steady supply to the global market is a testimony of its technology readiness and mass production capability.

In May 2024, the company inaugurated its first overseas R&D center in Paris-Saclay, France, to provide tailored technological solutions for the European market. Its first overseas Gigafactory project, located in Dunkirk, France, successfully completed both environmental and construction permitting processes by the end of 2024. Construction is scheduled to begin in 2026, with mass production of fourth-generation batteries starting in 2028.